Page 116 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 116

PIPING

2.66 CHAPTER TWO

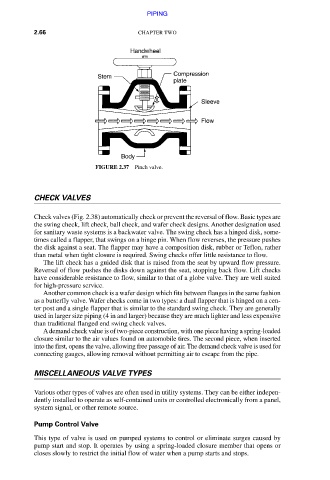

FIGURE 2.37 Pinch valve.

CHECK VALVES

Check valves (Fig. 2.38) automatically check or prevent the reversal of flow. Basic types are

the swing check, lift check, ball check, and wafer check designs. Another designation used

for sanitary waste systems is a backwater valve. The swing check has a hinged disk, some-

times called a flapper, that swings on a hinge pin. When flow reverses, the pressure pushes

the disk against a seat. The flapper may have a composition disk, rubber or Teflon, rather

than metal when tight closure is required. Swing checks offer little resistance to flow.

The lift check has a guided disk that is raised from the seat by upward flow pressure.

Reversal of flow pushes the disks down against the seat, stopping back flow. Lift checks

have considerable resistance to flow, similar to that of a globe valve. They are well suited

for high-pressure service.

Another common check is a wafer design which fits between flanges in the same fashion

as a butterfly valve. Wafer checks come in two types: a dual flapper that is hinged on a cen-

ter post and a single flapper that is similar to the standard swing check. They are generally

used in larger size piping (4 in and larger) because they are much lighter and less expensive

than traditional flanged end swing check valves.

A demand check value is of two-piece construction, with one piece having a spring-loaded

closure similar to the air values found on automobile tires. The second piece, when inserted

into the first, opens the valve, allowing free passage of air. The demand check valve is used for

connecting gauges, allowing removal without permitting air to escape from the pipe.

MISCELLANEOUS VALVE TYPES

Various other types of valves are often used in utility systems. They can be either indepen-

dently installed to operate as self-contained units or controlled electronically from a panel,

system signal, or other remote source.

Pump Control Valve

This type of valve is used on pumped systems to control or eliminate surges caused by

pump start and stop. It operates by using a spring-loaded closure member that opens or

closes slowly to restrict the initial flow of water when a pump starts and stops.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.