Page 153 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 153

SOLID-LIQUID SEPARATION AND INTERCEPTORS

SOLID-LIQUID SEPARATION AND INTERCEPTORS 3.21

installations. Second is the semiautomatic type, in which the grease stored in the top of the

unit is discharged through a special valved connection into a separate container. This is

done by running hot water through the unit for the purpose of removing the stored grease.

Third is an automatic unit that continuously removes grease from the effluent. This type is

only used for very large amounts of grease in large projects. A fourth type uses enzymes

added to the grease trap to break up the grease inside the unit and allow it to directly enter

the sanitary piping system.

The grease trap can be placed either under the floor or above the floor, depending on space

conditions available and method of grease removal preferred. The semiautomatic removal

requires an above-the-floor installation, usually under a sink or in a storage room.

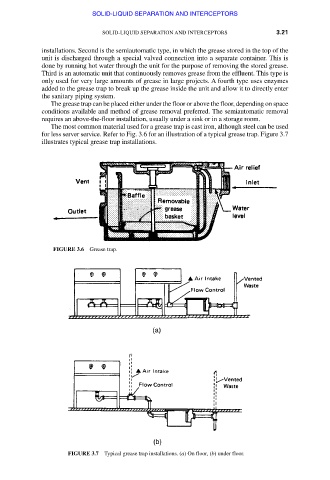

The most common material used for a grease trap is cast iron, although steel can be used

for less server service. Refer to Fig. 3.6 for an illustration of a typical grease trap. Figure 3.7

illustrates typical grease trap installations.

FIGURE 3.6 Grease trap.

FIGURE 3.7 Typical grease trap installations. (a) On floor, (b) under floor.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.