Page 159 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 159

SOLID-LIQUID SEPARATION AND INTERCEPTORS

SOLID-LIQUID SEPARATION AND INTERCEPTORS 3.27

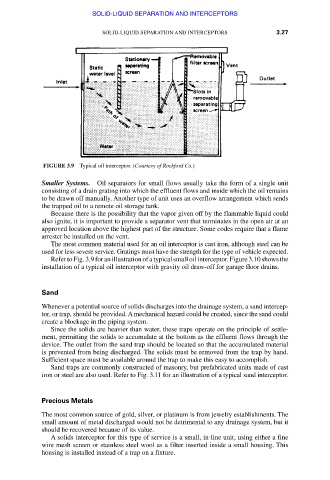

FIGURE 3.9 Typical oil interceptor. (Courtesy of Rockford Co.)

Smaller Systems. Oil separators for small flows usually take the form of a single unit

consisting of a drain grating into which the effluent flows and inside which the oil remains

to be drawn off manually. Another type of unit uses an overflow arrangement which sends

the trapped oil to a remote oil storage tank.

Because there is the possibility that the vapor given off by the flammable liquid could

also ignite, it is important to provide a separator vent that terminates in the open air at an

approved location above the highest part of the structure. Some codes require that a flame

arrester be installed on the vent.

The most common material used for an oil interceptor is cast iron, although steel can be

used for less severe service. Gratings must have the strength for the type of vehicle expected.

Refer to Fig. 3.9 for an illustration of a typical small oil interceptor. Figure 3.10 shows the

installation of a typical oil interceptor with gravity oil draw-off for garage floor drains.

Sand

Whenever a potential source of solids discharges into the drainage system, a sand intercep-

tor, or trap, should be provided. A mechanical hazard could be created, since the sand could

create a blockage in the piping system.

Since the solids are heavier than water, these traps operate on the principle of settle-

ment, permitting the solids to accumulate at the bottom as the effluent flows through the

device. The outlet from the sand trap should be located so that the accumulated material

is prevented from being discharged. The solids must be removed from the trap by hand.

Sufficient space must be available around the trap to make this easy to accomplish.

Sand traps are commonly constructed of masonry, but prefabricated units made of cast

iron or steel are also used. Refer to Fig. 3.11 for an illustration of a typical sand interceptor.

Precious Metals

The most common source of gold, silver, or platinum is from jewelry establishments. The

small amount of metal discharged would not be detrimental to any drainage system, but it

should be recovered because of its value.

A solids interceptor for this type of service is a small, in-line unit, using either a fine

wire mesh screen or stainless steel wool as a filter inserted inside a small housing. This

housing is installed instead of a trap on a fixture.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.