Page 193 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 193

WATER TREATMENT AND PURIFICATION

WATER TREATMENT AND PURIFICATION 4.29

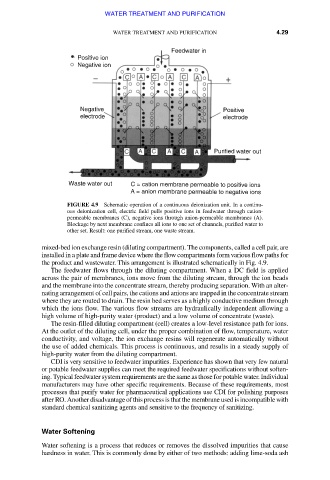

FIGURE 4.9 Schematic operation of a continuous deionization unit. In a continu-

ous deionization cell, electric field pulls positive ions in feedwater through cation-

permeable membranes (C), negative ions through anion-permeable membranes (A).

Blockage by next membrane confines all ions to one set of channels, purified water to

other set. Result: one purified stream, one waste stream.

mixed-bed ion exchange resin (diluting compartment). The components, called a cell pair, are

installed in a plate and frame device where the flow compartments form various flow paths for

the product and wastewater. This arrangement is illustrated schematically in Fig. 4.9.

The feedwater flows through the diluting compartment. When a DC field is applied

across the pair of membranes, ions move from the diluting stream, through the ion beads

and the membrane into the concentrate stream, thereby producing separation. With an alter-

nating arrangement of cell pairs, the cations and anions are trapped in the concentrate stream

where they are routed to drain. The resin bed serves as a highly conductive medium through

which the ions flow. The various flow streams are hydraulically independent allowing a

high volume of high-purity water (product) and a low volume of concentrate (waste).

The resin-filled diluting compartment (cell) creates a low-level resistance path for ions.

At the outlet of the diluting cell, under the proper combination of flow, temperature, water

conductivity, and voltage, the ion exchange resins will regenerate automatically without

the use of added chemicals. This process is continuous, and results in a steady supply of

high-purity water from the diluting compartment.

CDI is very sensitive to feedwater impurities. Experience has shown that very few natural

or potable feedwater supplies can meet the required feedwater specifications without soften-

ing. Typical feedwater system requirements are the same as those for potable water. Individual

manufacturers may have other specific requirements. Because of these requirements, most

processes that purify water for pharmaceutical applications use CDI for polishing purposes

after RO. Another disadvantage of this process is that the membrane used is incompatible with

standard chemical sanitizing agents and sensitive to the frequency of sanitizing.

Water Softening

Water softening is a process that reduces or removes the dissolved impurities that cause

hardness in water. This is commonly done by either of two methods: adding lime-soda ash

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.