Page 198 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 198

WATER TREATMENT AND PURIFICATION

4.34 CHAPTER FOUR

Membrane Selection

System performance is determined by considering the following factors that influence the

capacity of the individual membranes selected:

1. Operating pH

2. Chlorine tolerance

3. Temperature of the feedwater

4. Feedwater quality, usually measured as SDI

5. Types of impurities and previous feedwater treatment

6. Membrane flux

7. Number of operating hours

8. Resistance to biodegradation and ability to be sanitized

9. Rejection characteristics. Typical RO systems remove the following contaminants to the

following levels:

Inorganic ions 93–99%

Dissolved organics (>300 MW) >99%

Particulates >99%

Microorganisms >99%

The selection of a system configuration must consider the following:

1. Maximum recovery

2. Fouling properties and resistance

3. Production rate per unit volume

There are only a small number of polymers that have the necessary characteristics to

function as semipermeable membranes.

1. Thin film composite of various polymer materials

2. Polyamide

3. Cellulose acetate

4. Cellulose triacetate

5. Polysulfone

Typical characteristics and a comparison of these membranes are given in Table 4.8.

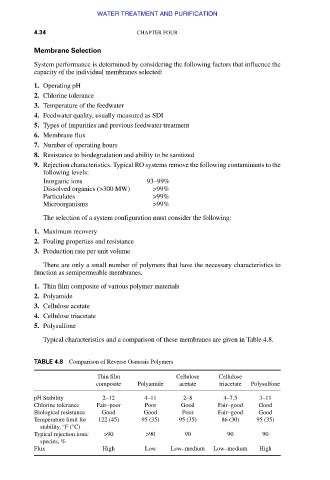

TABLE 4.8 Comparison of Reverse Osmosis Polymers

Thin film Cellulose Cellulose

composite Polyamide acetate triacetate Polysulfone

pH Stability 2–12 4–11 2–8 4–7.5 3–11

Chlorine tolerance Fair–poor Poor Good Fair–good Good

Biological resistance Good Good Poor Fair–good Good

Temperature limit for 122 (45) 95 (35) 95 (35) 86 (30) 95 (35)

stability, °F (°C)

Typical rejection ionic >90 >90 90 90 90

species, %

Flux High Low Low–medium Low–medium High

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.