Page 70 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 70

PIPING

2.20 CHAPTER TWO

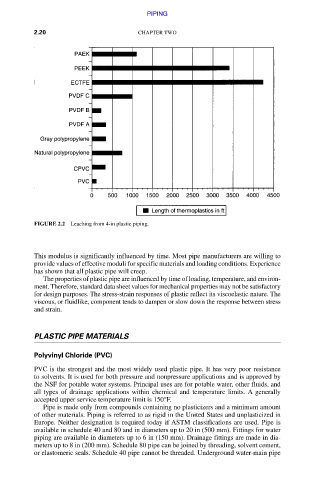

FIGURE 2.2 Leaching from 4-in plastic piping.

This modulus is significantly influenced by time. Most pipe manufacturers are willing to

provide values of effective moduli for specific materials and loading conditions. Experience

has shown that all plastic pipe will creep.

The properties of plastic pipe are influenced by time of loading, temperature, and environ-

ment. Therefore, standard data sheet values for mechanical properties may not be satisfactory

for design purposes. The stress-strain responses of plastic reflect its viscoelastic nature. The

viscous, or fluidlike, component tends to dampen or slow down the response between stress

and strain.

PLASTIC PIPE MATERIALS

Polyvinyl Chloride (PVC)

PVC is the strongest and the most widely used plastic pipe. It has very poor resistance

to solvents. It is used for both pressure and nonpressure applications and is approved by

the NSF for potable water systems. Principal uses are for potable water, other fluids, and

all types of drainage applications within chemical and temperature limits. A generally

accepted upper service temperature limit is 150°F.

Pipe is made only from compounds containing no plasticizers and a minimum amount

of other materials. Piping is referred to as rigid in the United States and unplasticized in

Europe. Neither designation is required today if ASTM classifications are used. Pipe is

available in schedule 40 and 80 and in diameters up to 20 in (500 mm). Fittings for water

piping are available in diameters up to 6 in (150 mm). Drainage fittings are made in dia-

meters up to 8 in (200 mm). Schedule 80 pipe can be joined by threading, solvent cement,

or elastomeric seals. Schedule 40 pipe cannot be threaded. Underground water-main pipe

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.