Page 263 - Failure Analysis Case Studies II

P. 263

248

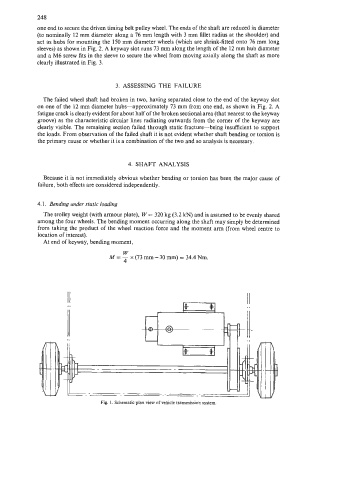

one end to secure the driven timing belt pulley wheel. The ends of the shaft are reduced in diameter

(to nominally 12 mm diameter along a 76 mm length with 3 mm fillet radius at the shoulder) and

act as hubs for mounting the 150 mm diameter wheels (which are shrink-fitted onto 76 mm long

sleeves) as shown in Fig. 2. A keyway slot runs 73 mm along the length of the 12 mm hub diameter

and a M6 screw fits in the sleeve to secure the wheel from moving axially along the shaft as more

clearly illustrated in Fig. 3.

3. ASSESSING THE FAILURE

The failed wheel shaft had broken in two, having separated close to the end of the keyway slot

on one of the 12 mm diameter hubs-approximately 73 mm from one end, as shown in Fig. 2. A

fatigue crack is clearly evident for about half of the broken sectional area (that nearest to the keyway

groove) as the characteristic circular lines radiating outwards from the corner of the keyway are

clearly visible. The remaining section failed through static fracture-being insufficient to support

the loads. From observation of the failed shaft it is not evident whether shaft bending or torsion is

the primary cause or whether it is a combination of the two and so analysis is necessary.

4. SHAFT ANALYSIS

Because it is not immediately obvious whether bending or torsion has been the major cause of

failure, both effects are considered independently.

4.1. Bending under static loading

The trolley weight (with annour plate), W = 320 kg (3.2 kN) and is assumed to be evenly shared

among the four wheels. The bending moment occurring along the shaft may simply be determined

from taking the product of the wheel reaction force and the moment arm (from wheel centre to

location of interest).

At end of keyway, bending moment,

W

M = - (73 mm-30 mm) = 34.4 Nm.

x

4

II 4-1

I1 Ilh

Fig. 1. Schematic plan view of vehicle transmission system.