Page 268 - Failure Analysis Case Studies II

P. 268

253

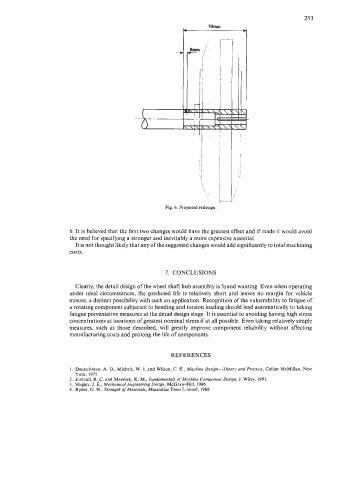

Fig. 6. Proposed redesign.

6. It is believed that the first two changes would have the greatest effect and if made it would avoid

the need for specifying a stronger and inevitably a more expensive material.

It is not thought likely that any of the suggested changes would add significantly to total machining

costs.

7. CONCLUSIONS

Clearly, the detail design of the wheel shaft hub assembly is found wanting. Even when operating

under ideal circumstances, the predicted life is relatively short and leaves no margin for vehicle

misuse, a distinct possibility with such an application. Recognition of the vulnerability to fatigue of

a rotating component subjected to bending and torsion loading should lead automatically to taking

fatigue preventative measures at the detail design stage. It is essential to avoiding having high stress

concentrations at locations of greatest nominal stress if at all possible. Even taking relatively simple

measures, such as those described, will greatly improve component reliability without affecting

manufacturing costs and prolong the life of components.

REFERENCES

1. Deutschman, A. D., Michels, W. 1. and Wilson, C. E., Machine Design-Theory and Practice, Collier McMillan, New

York, 1975.

2. Juvinall, R. C. and Marshek, K. M., Fundamentals qfhfachine Component Design, J. Wiley, 1991.

3. Shigley, J. E., Mechanical Engineering Design, McGraw-Hill, 1986.

4. Ryder, G. H., Strength of Materials, Macmillan Press Limited, 1969.