Page 272 - Failure Analysis Case Studies II

P. 272

257

Sled

Steel Shafts

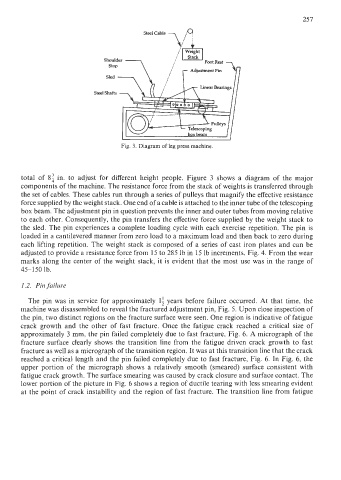

Fig. 3. Diagram of leg press machine.

total of 8: in. to adjust for different height people. Figure 3 shows a diagram of the major

components of the machine. The resistance force from the stack of weights is transferred through

the set of cables. These cables run through a series of pulleys that magnify the effective resistance

force supplied by the weight stack. One end of a cable is attached to the inner tube of the telescoping

box beam. The adjustment pin in question prevents the inner and outer tubes from moving relative

to each other. Consequently, the pin transfers the effective force supplied by the weight stack to

the sled. The pin experiences a complete loading cycle with each exercise repetition. The pin is

loaded in a cantilevered manner from zero load to a maximum load and then back to zero during

each lifting repetition. The weight stack is composed of a series of cast iron plates and can be

adjusted to provide a resistance force from 15 to 285 lb in 15 lb increments, Fig. 4. From the wear

marks along the center of the weight stack, it is evident that the most use was in the range of

45-1 50 lb.

I .2. Pin,failure

The pin was in service for approximately 1: years before failure occurred. At that time, the

machine was disassembled to reveal the fractured adjustment pin, Fig. 5. Upon close inspection of

the pin, two distinct regions on the fracture surface were seen. One region is indicative of fatigue

crack growth and the other of fast fracture. Once the fatigue crack reached a critical size of

approximately 3 mm, the pin failed completely due to fast fracture, Fig. 6. A micrograph of the

fracture surface clearly shows the transition line from the fatigue driven crack growth to fast

fracture as well as a micrograph of the transition region. It was at this transition line that the crack

reached a critical length and the pin failed completely due to fast fracture, Fig. 6. In Fig. 6, the

upper portion of the micrograph shows a relatively smooth (smeared) surface consistent with

fatigue crack growth. The surface smearing was caused by crack closure and surface contact. The

lower portion of the picture in Fig. 6 shows a region of ductile tearing with less smearing evident

at the point of crack instability and the region of fast fracture. The transition line from fatigue