Page 273 - Failure Analysis Case Studies II

P. 273

258

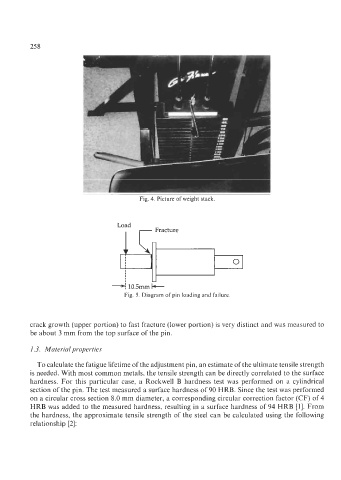

Fig. 4. Picture of weight stack.

Load

0

Fig. 5. Diagram of pin loading and failure.

crack growth (upper portion) to fast fracture (lower portion) is very distinct and was measured to

be about 3 mm from the top surface of the pin.

I .3. Material properties

To calculate the fatigue lifetime of the adjustment pin, an estimate of the ultimate tensile strength

is needed. With most common metals, the tensile strength can be directly correlated to the surface

hardness. For this particular case, a Rockwell B hardness test was performed on a cylindrical

section of the pin. The test measured a surface hardness of 90 HRB. Since the test was performed

on a circular cross section 8.0 mm diameter, a corresponding circular correction factor (CF) of 4

HRB was added to the measured hardness, resulting in a surface hardness of 94 HRB [ 13. From

the hardness, the approximate tensile strength of the steel can be calculated using the following

relationship [2]: