Page 330 - Failure Analysis Case Studies II

P. 330

315

In addition to pitting of the silver plating, there were burnt areas where it appeared as if silver

plating had been melted by electrical arcing.

Closer investigation of the pitted areas seemed to show that corrosion on the waveguide internal

passages probably started on the exposed silver plated surface. It is theorized that these pits, however

formed, allowed attack of the underlying copper bearing base material.

A chemical analysis using X-ray diffraction analysis, subsequently verified by Fourier transform

infrared spectroscopy and energy dispersive X-ray spectroscopy, revealed that the debris is primarily

copper hydroxy nitrate Cu(OH),N03. To determine how it got there, a laboratory test was per-

formed to try to create the same debris on clean waveguide samples by placing on them a small

amount of nitric acid. Two hours later, a blue color was observed in the acid. After about 12 h, blue

crystals began forming at the silver plated interface. After 5 days, most of the solution had been

replaced by green corrosion analyzed as a copper hydroxy nitrate. Nitric acid clearly caused

the corrosion. Its source could be either faulty fabrication processes or arcing induced chemical

reactions.

2. FABRICATION PROCESS

The silver plating on the brass waveguide is applied after the brass has undergone a multi step

surface preparation process. First, the brass surface is cleaned and etched in a caustic cleaning

solution for 5-60 s. After subsequent rinsing under running tap water, the brass is immersed in a

bright dip solution for 5-20 s. This removes scratches and oxide, making the brass look shiny. The

bright dip solution is composed of 5-10% tap water, 60-75% sulfuric acid, 20-35% nitric acid. To

remove the bright dip, parts are washed in running tap water. The use of pumice and a brush is

required for assemblies. The bright dip vendor specifies that this cleaning technique is suffcient.

Once bright dipping is complete, parts should be first immersed in clean running water, then

boiling hot water, and then dried. To avoid contamination between one dip operation and another,

parts should be rinsed in running water, hot water and then dried at each step [l].

Both silver and copper bright dips exist to make either copper or silver shiny. Once silver plating

was complete, a bright dip step may have been inadvertently included despite its lack in vendor

process specifications. For instance, a silver bright dip may have been performed to relieve the

effects of poor silver plating, inadvertently leaving behind an acidic residue.

3. ARCING INDUCED CHEMICAL REACTIONS

If nitric acid was indeed produced by arcing, nitric oxide (NO) would need to be present. Colorless

and noncombustible, nitric oxide can be produced from atmospheric oxygen and nitrogen in the

presence of an electric arc. In this instance, such production is possible-there was evidence of

arcing on the waveguide surface. In addition, arcing could have initiated pits in the silver plating,

exposing the underlying copper bearing base material to chemical attack.

A similar incident of corrosion in an aircraft waveguide system occurred about 20 years ago. In

that case, arcs were created in a clean noncorroded waveguide while gas samples were taken for an

analysis by mass spectrometry. An analysis of two samples is shown in Table 1.

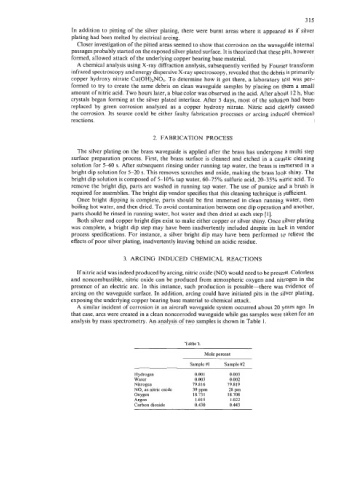

Table 1.

Mole percent

Sample #I Sample #2

Hydrogen 0.001 0.003

Water 0.003 0.002

Nitrogen 79.816 79.819

NO, as nitric oxide 39 PPm 28 pm

Oxygen 18.731 18.708

Argon 1.015 1.022

Carbon dioxide 0.430 0.443