Page 347 - Failure Analysis Case Studies II

P. 347

332

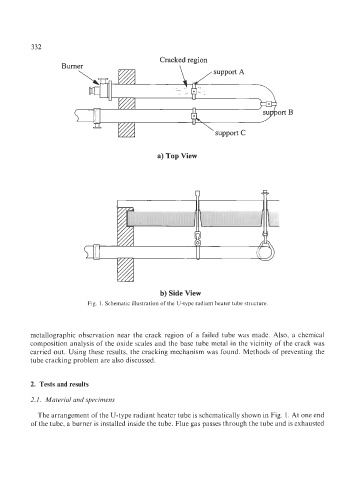

Cracked region

Burner

\ support A

a) Top View

b) Side View

Fig. 1. Schematic illustration of the U-type radiant heater tube structure.

metallographic observation near the crack region of a failed tube was made. Also, a chemical

composition analysis of the oxide scales and the base tube metal in the vicinity of the crack was

carried out. Using these results, the cracking mechanism was found. Methods of preventing the

tube cracking problem are also discussed.

2. Tests and results

2.1. Material and specimens

The arrangement of the U-type radiant heater tube is schematically shown in Fig. 1. At one end

of the tube, a burner is installed inside the tube. Flue gas passes through the tube and is exhausted