Page 429 - Failure Analysis Case Studies II

P. 429

413

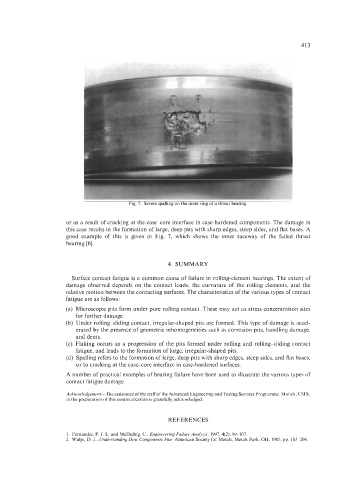

Fig. 7. Severe spalling on the inner ring of a thrust bearing

or as a result of cracking at the case-core interface in case-hardened components. The damage in

this case results in the formation of large, deep pits with sharp edges, steep sides, and flat bases. A

good example of this is given in Fig. 7, which shows the inner raceway of the failed thrust

bearing [6].

4. SUMMARY

Surface contact fatigue is a common cause of failure in rolling-element bearings. The extent of

damage observed depends on the contact loads, the curvature of the rolling elements, and the

relative motion between the contacting surfaces. The characteristics of the various types of contact

fatigue are as follows:

(a) Microscopic pits form under pure rolling contact. These may act as stress concentration sites

for further damage.

(b) Under rolling-sliding contact, irregular-shaped pits are formed. This type of damage is accel-

erated by the presence of geometric inhomogeneities such as corrosion pits, handling damage,

and dents.

(c) Flaking occurs as a progression of the pits formed under rolling and rolling-sliding contact

fatigue, and leads to the formation of large, irregular-shaped pits.

(d) Spalling refers to the formation of large, deep pits with sharp edges, steep sides, and flat bases,

or to cracking at the case-core interface in case-hardened surfaces.

A number of practical examples of bearing failure have been used to illustrate the various types of

contact fatigue damage.

Acknowledgement-The assistance of the staff of the Advanced Engineering and Testing Services Programme, Mattek, CSIR,

in the preparation of this communication is gratefully acknowledged.

REFERENCES

1. Fernandes, P. J. L. and McDuling, C., Engineeering Failure Analysis, 1997, 4(2), 99-107.

2. Wulpi, D. J., Understanding How Components Fair. American Society for Metals, Metals Park, OH, 1985, pp. 183-204.