Page 455 - Failure Analysis Case Studies II

P. 455

43 8

O.D.

O.D.

x 75

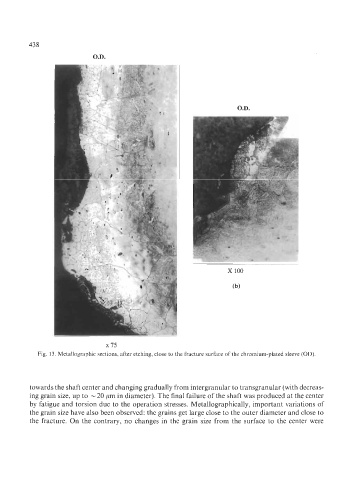

Fig. 13. Metallographic sections, after etching, close to the fracture surface of the chromium-plated sleeve (OD).

towards the shaft center and changing gradually from intergranular to transgranular (with decreas-

ing grain size, up to - 20 ,um in diameter). The final failure of the shaft was produced at the center

by fatigue and torsion due to the operation stresses. Metallographically, important variations of

the grain size have also been observed: the grains get large close to the outer diameter and close to

the fracture. On the contrary, no changes in the grain size from the surface to the center were