Page 450 - Failure Analysis Case Studies II

P. 450

433

I

I O.D.

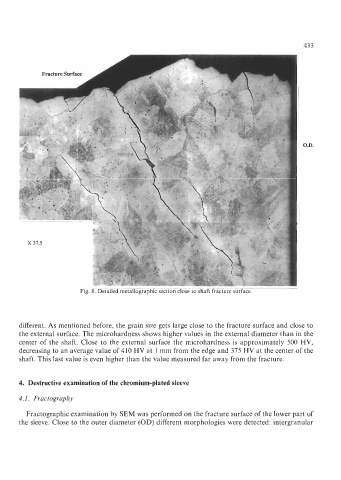

Fig. 8. Detailed metallographic section close to shaft fracture surface.

different. As mentioned before, the grain size gets large close to the fracture surface and close to

the external surface. The microhardness shows higher values in the external diameter than in the

center of the shaft. Close to the external surface the microhardness is approximately 500 HV,

decreasing to an average value of 410 HV at 1 mm from the edge and 375 HV at the center of the

shaft. This last value is even higher than the value measured far away from the fracture.

4. Destructive examination of the chromium-plated sleeve

4.1. Fractography

Fractographic examination by SEM was performed on the fracture surface of the lower part of

the sleeve. Close to the outer diameter (OD) different morphologies were detected: intergranular