Page 366 - Fair, Geyer, and Okun's Water and wastewater engineering : water supply and wastewater removal

P. 366

JWCL344_ch09_297-332.qxd 8/2/10 9:54 PM Page 326

326 Chapter 9 Cross-Connection Control

check valve 1. The supply pressure is then reduced by a predetermined amount. The pressure in

the central chamber is maintained lower than the incoming supply pressure through the opera-

tion of the relief valve, which discharges to the atmosphere whenever the central chamber pres-

sure approaches within a few psi of the inlet pressure. Check valve 2 is lightly loaded to open

with a pressure drop of l psi (7 kPa) in the direction of flow and is independent of the pressure

required to open the relief valve. In the event that the pressure increases downstream from the

device, tending to reverse the direction of flow, check valve 2 closes, preventing backflow.

Because all valves may leak as a result of wear or obstruction, the protection provided by the

check valves is not considered sufficient. If some obstruction prevents check valve 2 from clos-

ing tightly, the leakage back into the central chamber would increase the pressure in this zone,

the relief valve would open, and flow would be discharged to the atmosphere.

When the supply pressure drops to the minimum differential required to operate the relief

valve, the pressure in the central chamber should be atmospheric; if the inlet pressure should be-

come less than atmospheric pressure, the relief valve should remain fully open to the atmosphere

to discharge any backflow water that is the result of backpressure and leakage of check valve 2.

Malfunctioning of one or both of the check valves or relief valve should always be

indicated by a discharge of water from the relief port. Under no circumstances should plug-

ging of the relief port be permitted because the device depends on an open port for safe

operation. The pressure loss through the device may be expected to average between 10 and

20 psi (69.4 and 138.8 kPa) within the normal range of operation, depending on the size and

flow rate of the device.

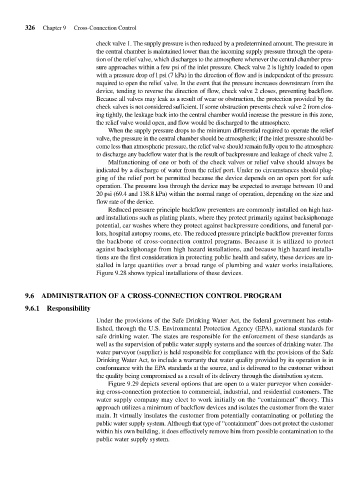

Reduced pressure principle backflow preventers are commonly installed on high haz-

ard installations such as plating plants, where they protect primarily against backsiphonage

potential, car washes where they protect against backpressure conditions, and funeral par-

lors, hospital autopsy rooms, etc. The reduced pressure principle backflow preventer forms

the backbone of cross-connection control programs. Because it is utilized to protect

against backsiphonage from high hazard installations, and because high hazard installa-

tions are the first consideration in protecting public health and safety, these devices are in-

stalled in large quantities over a broad range of plumbing and water works installations.

Figure 9.28 shows typical installations of these devices.

9.6 ADMINISTRATION OF A CROSS-CONNECTION CONTROL PROGRAM

9.6.1 Responsibility

Under the provisions of the Safe Drinking Water Act, the federal government has estab-

lished, through the U.S. Environmental Protection Agency (EPA), national standards for

safe drinking water. The states are responsible for the enforcement of these standards as

well as the supervision of public water supply systems and the sources of drinking water. The

water purveyor (supplier) is held responsible for compliance with the provisions of the Safe

Drinking Water Act, to include a warranty that water quality provided by its operation is in

conformance with the EPA standards at the source, and is delivered to the customer without

the quality being compromised as a result of its delivery through the distribution system.

Figure 9.29 depicts several options that are open to a water purveyor when consider-

ing cross-connection protection to commercial, industrial, and residential customers. The

water supply company may elect to work initially on the “containment” theory. This

approach utilizes a minimum of backflow devices and isolates the customer from the water

main. It virtually insulates the customer from potentially contaminating or polluting the

public water supply system. Although that type of “containment” does not protect the customer

within his own building, it does effectively remove him from possible contamination to the

public water supply system.