Page 362 - Fair, Geyer, and Okun's Water and wastewater engineering : water supply and wastewater removal

P. 362

JWCL344_ch09_297-332.qxd 8/2/10 9:54 PM Page 322

322 Chapter 9 Cross-Connection Control

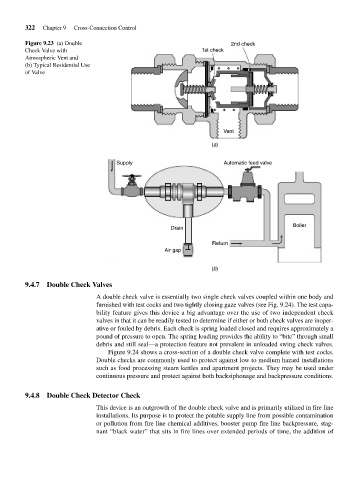

Figure 9.23 (a) Double 2nd check

Check Valve with 1st check

Atmospheric Vent and

(b) Typical Residential Use

of Valve

Vent

(a)

Supply Automatic feed valve

Boiler

Drain

Return

Air gap

(b)

9.4.7 Double Check Valves

A double check valve is essentially two single check valves coupled within one body and

furnished with test cocks and two tightly closing gaze valves (see Fig. 9.24). The test capa-

bility feature gives this device a big advantage over the use of two independent check

valves in that it can be readily tested to determine if either or both check valves are inoper-

ative or fouled by debris. Each check is spring loaded closed and requires approximately a

pound of pressure to open. The spring loading provides the ability to “bite” through small

debris and still seal—a protection feature not prevalent in unloaded swing check valves.

Figure 9.24 shows a cross-section of a double check valve complete with test cocks.

Double checks are commonly used to protect against low to medium hazard installations

such as food processing steam kettles and apartment projects. They may be used under

continuous pressure and protect against both backsiphonage and backpressure conditions.

9.4.8 Double Check Detector Check

This device is an outgrowth of the double check valve and is primarily utilized in fire line

installations. Its purpose is to protect the potable supply line from possible contamination

or pollution from fire line chemical additives, booster pump fire line backpressure, stag-

nant “black water” that sits in fire lines over extended periods of time, the addition of