Page 59 - Fair, Geyer, and Okun's Water and wastewater engineering : water supply and wastewater removal

P. 59

JWCL344_ch01_001-028.qxd 8/2/10 9:12 PM Page 22

22 Chapter 1 Introduction to Water Systems

Service or

Street curb box Foundation wall

Supply to

Frost building

depth

Corporation Stop and waste cock

cock or stop

Caulked

Goose neck Check

pipe

Union Union valve Drip

sleeve

valve

Curb cock Valve Meter Testing Valve

Street Service pipe or stop tee

main Hose end

Basement floor

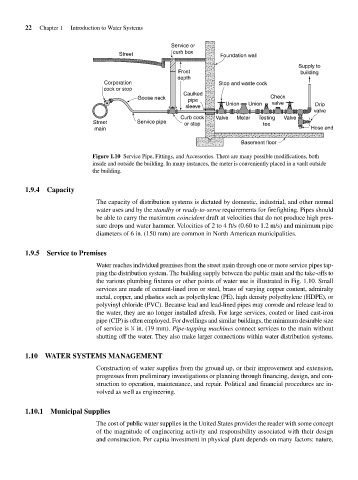

Figure 1.10 Service Pipe, Fittings, and Accessories. There are many possible modifications, both

inside and outside the building. In many instances, the meter is conveniently placed in a vault outside

the building.

1.9.4 Capacity

The capacity of distribution systems is dictated by domestic, industrial, and other normal

water uses and by the standby or ready-to-serve requirements for firefighting. Pipes should

be able to carry the maximum coincident draft at velocities that do not produce high pres-

sure drops and water hammer. Velocities of 2 to 4 ft/s (0.60 to 1.2 m/s) and minimum pipe

diameters of 6 in. (150 mm) are common in North American municipalities.

1.9.5 Service to Premises

Water reaches individual premises from the street main through one or more service pipes tap-

ping the distribution system. The building supply between the public main and the take-offs to

the various plumbing fixtures or other points of water use is illustrated in Fig. 1.10. Small

services are made of cement-lined iron or steel, brass of varying copper content, admiralty

metal, copper, and plastics such as polyethylene (PE), high density polyethylene (HDPE), or

polyvinyl chloride (PVC). Because lead and lead-lined pipes may corrode and release lead to

the water, they are no longer installed afresh. For large services, coated or lined cast-iron

pipe (CIP) is often employed. For dwellings and similar buildings, the minimum desirable size

of service is ⁄4 in. (19 mm). Pipe-tapping machines connect services to the main without

3

shutting off the water. They also make larger connections within water distribution systems.

1.10 WATER SYSTEMS MANAGEMENT

Construction of water supplies from the ground up, or their improvement and extension,

progresses from preliminary investigations or planning through financing, design, and con-

struction to operation, maintenance, and repair. Political and financial procedures are in-

volved as well as engineering.

1.10.1 Municipal Supplies

The cost of public water supplies in the United States provides the reader with some concept

of the magnitude of engineering activity and responsibility associated with their design

and construction. Per capita investment in physical plant depends on many factors: nature,