Page 116 - Fiber Fracture

P. 116

FRACTURE PROCESSES IN OXIDE CERAMIC FIBRES 101

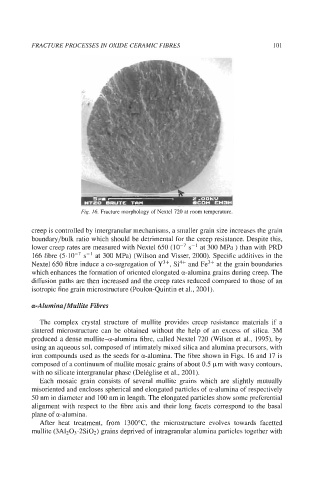

Fig. 16. Fracture morphology of Nextel 720 at room temperature.

creep is controlled by intergranular mechanisms, a smaller grain size increases the grain

boundary/bulk ratio which should be detrimental for the creep resistance. Despite this,

lower creep rates are measured with Nextel 650 ( lop7 ssl at 300 MPa ) than with PRD

166 fibre (5.10-7 s-' at 300 MPa) (Wilson and Visser, 2000). Specific additives in the

Nextel 650 fibre induce a co-segregation of Y3+, Si4+ and Fe3+ at the grain boundaries

which enhances the formation of oriented elongated a-alumina grains during creep. The

diffusion paths are then increased and the creep rates reduced compared to those of an

isotropic fine grain microstructure (Poulon-Quintin et al., 2001).

a-Alumina/Mullite Fibres

The complex crystal structure of mullite provides creep resistance materials if a

sintered microstructure can be obtained without the help of an excess of silica. 3M

produced a dense mullite-a-alumina fibre, called Nextel 720 (Wilson et al., 1995), by

using an aqueous sol, composed of intimately mixed silica and alumina precursors, with

iron compounds used as the seeds for a-alumina. The fibre shown in Figs. 16 and 17 is

composed of a continuum of mullite mosaic grains of about 0.5 p,m with wavy contours,

with no silicate intergranular phase (DelCglise et al., 2001).

Each mosaic grain consists of several mullite grains which are slightly mutually

misoriented and encloses spherical and elongated particles of a-alumina of respectively

50 nm in diameter and 100 nm in length. The elongated particles show some preferential

alignment with respect to the fibre axis and their long facets correspond to the basal

plane of a-alumina.

After heat treatment, from 13OO0C, the microstructure evolves towards facetted

mullite (3A1203.2Si02) grains deprived of intragranular alumina particles together with