Page 119 - Fiber Fracture

P. 119

104 M.-H. Berger

Slow crack

arowth

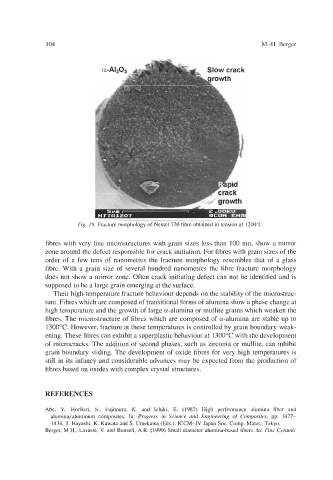

Fig. 19. Fracture morphology of Nextel 720 fibre obtained in tension at 1200°C.

fibres with very fine microstructures with grain sizes less than 100 nm, show a mirror

zone around the defect responsible for crack initiation. For fibres with grain sizes of the

order of a few tens of nanometres the fracture morphology resembles that of a glass

fibre. With a grain size of several hundred nanometres the fibre fracture morphology

does not show a mirror zone. Often crack initiating defect can not be identified and is

supposed to be a large grain emerging at the surface.

Their high-temperature fracture behaviour depends on the stability of the microstruc-

ture. Fibres which are composed of transitional forms of alumina show a phase change at

high temperature and the growth of large a-alumina or mullite grains which weaken the

fibres. The microstructure of fibres which are composed of a-alumina are stable up to

1300°C. However, fracture at these temperatures is controlled by grain boundary weak-

ening. These fibres can exhibit a superplastic behaviour at 1300°C with the development

of microcracks. The addition of second phases, such as zirconia or mullite, can inhibit

grain boundary sliding. The development of oxide fibres for very high temperatures is

still in its infancy and considerable advances may be expected from the production of

fibres based on oxides with complex crystal structures.

REFERENCES

Abe, Y., Horikiri, S., Fujimura, K. and Ichiki, E. (1982) High performance alumina fiber and

alumina/aluminum composites. In: Progress in Science and Engineering of Composites, pp. 1427-

1434, T. Hayashi, K. Kawata and S. Umekawa (Eds.). ICCM-IV Japan SOC. Comp. Mater., Tokyo.

Berger, M.H., Lavaste, V. and Bunsell, A.R. (1999) Small diameter alumina-based fibers. In: Fine Ceramic