Page 277 - Fiber Fracture

P. 277

260 K. Yoshida

4 1.35+ 4 1.30 a = 13"

Necking

I i I

0 150 300 450

Drawing length I (mm)

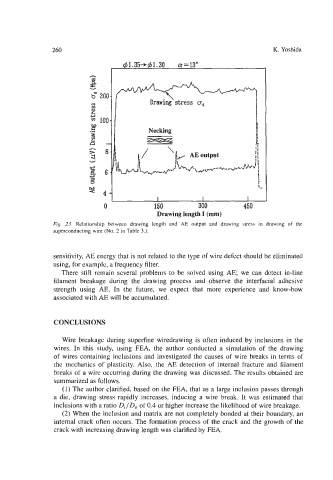

Fig. 23. Relationship between drawing length and AE output and drawing stress in drawing of the

superconducting wire (No. 2 in Table 3.).

sensitivity, AE energy that is not related to the type of wire defect should be eliminated

using, for example, a frequency filter.

There still remain several problems to be solved using AE; we can detect in-line

filament breakage during the drawing process and observe the interfacial adhesive

strength using AE. In the future, we expect that more experience and know-how

associated with AE will be accumulated.

CONCLUSIONS

Wire breakage during superfine wiredrawing is often induced by inclusions in the

wires. In this study, using FEA, the author conducted a simulation of the drawing

of wires containing inclusions and investigated the causes of wire breaks in terms of

the mechanics of plasticity. Also, the AE detection of internal fracture and filament

breaks of a wire occurring during the drawing was discussed. The results obtained are

summarized as follows.

(1) The author clarified, based on the FEA, that as a large inclusion passes through

a die, drawing stress rapidly increases, inducing a wire break. It was estimated that

inclusions with a ratio Di/Do of 0.4 or higher increase the likelihood of wire breakage.

(2) When the inclusion and matrix are not completely bonded at their boundary, an

internal crack often occurs. The formation process of the crack and the growth of the

crack with increasing drawing length was clarified by FEA.