Page 340 - Fiber Fracture

P. 340

322 C. Viney

c

0 Subunit in growing fibre 0 Previous nucleation site

Current nucleation site First subunit of new fibril

Fig. 8. Mechanism of collagen fibril growth in sea cucumber dermis and sea urchin ligament, based on

literature descriptions (Trotter et al., 1998, 2000a). The mechanism ensures a tapered shape and a consistent

axial ratio.

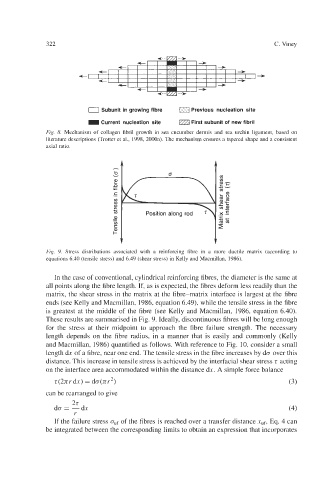

Fig. 9. Stress distributions associated with a reinforcing fibre in a more ductile matrix (according to

equations 6.40 (tensile stress) and 6.49 (shear stress) in Kelly and Macmillan, 1986).

In the case of conventional, cylindrical reinforcing fibres, the diameter is the same at

all points along the fibre length. If, as is expected, the fibres deform less readily than the

matrix, the shear stress in the matrix at the fibre-matrix interface is largest at the fibre

ends (see Kelly and Macmillan, 1986, equation 6.49), while the tensile stress in the fibre

is greatest at the middle of the fibre (see Kelly and Macmillan, 1986, equation 6.40).

These results are summarised in Fig. 9. Ideally, discontinuous fibres will be long enough

for the stress at their midpoint to approach the fibre failure strength. The necessary

length depends on the fibre radius, in a manner that is easily and commonly (Kelly

and Macmillan, 1986) quantified as follows. With reference to Fig. 10, consider a small

length dx of a fibre, near one end. The tensile stress in the fibre increases by do over this

distance. This increase in tensile stress is achieved by the interfacial shear stress t acting

on the interface area accommodated within the distance dx. A simple force balance

t(2nrdx) = do(nr2) (3)

can be rearranged to give

2t

do=-& (4)

r

If the failure stress o,,f of the fibres is reached over a transfer distance x,f, Eq. 4 can

be integrated between the corresponding limits to obtain an expression that incorporates