Page 153 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 153

134 Fluid Mechanics, Thermodynamics of Turbomachinery

4. In a Parson’s reaction turbine the rotor blades are similar to the stator blades but with

the angles measured in the opposite direction. The efflux angle relative to each row of blades

is 70 deg from the axial direction, the exit velocity of steam from the stator blades is 160 m/s,

the blade speed is 152.5 m/s and the axial velocity is constant. Determine the specific work

done by the steam per stage.

A turbine of 80% internal efficiency consists of ten such stages as described above and

receives steam from the stop valve at 1.5 MPa and 300 ° C. Determine, with the aid of a

Mollier chart, the condition of the steam at outlet from the last stage.

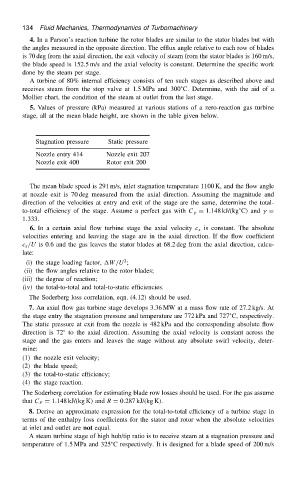

5. Values of pressure (kPa) measured at various stations of a zero-reaction gas turbine

stage, all at the mean blade height, are shown in the table given below.

Stagnation pressure Static pressure

Nozzle entry 414 Nozzle exit 207

Nozzle exit 400 Rotor exit 200

The mean blade speed is 291 m/s, inlet stagnation temperature 1100 K, and the flow angle

at nozzle exit is 70 deg measured from the axial direction. Assuming the magnitude and

direction of the velocities at entry and exit of the stage are the same, determine the total-

to-total efficiency of the stage. Assume a perfect gas with C p D 1.148 kJ/(kg ° C) and

D

1.333.

6. In a certain axial flow turbine stage the axial velocity c x is constant. The absolute

velocities entering and leaving the stage are in the axial direction. If the flow coefficient

c x /U is 0.6 and the gas leaves the stator blades at 68.2 deg from the axial direction, calcu-

late:

2

(i) the stage loading factor, W/U ;

(ii) the flow angles relative to the rotor blades;

(iii) the degree of reaction;

(iv) the total-to-total and total-to-static efficiencies.

The Soderberg loss correlation, eqn. (4.12) should be used.

7. An axial flow gas turbine stage develops 3.36 MW at a mass flow rate of 27.2 kg/s. At

the stage entry the stagnation pressure and temperature are 772 kPa and 727 ° C, respectively.

The static pressure at exit from the nozzle is 482 kPa and the corresponding absolute flow

direction is 72 ° to the axial direction. Assuming the axial velocity is constant across the

stage and the gas enters and leaves the stage without any absolute swirl velocity, deter-

mine:

(1) the nozzle exit velocity;

(2) the blade speed;

(3) the total-to-static efficiency;

(4) the stage reaction.

The Soderberg correlation for estimating blade row losses should be used. For the gas assume

that C P D 1.148 kJ/(kg K) and R D 0.287 kJ/(kg K).

8. Derive an approximate expression for the total-to-total efficiency of a turbine stage in

terms of the enthalpy loss coefficients for the stator and rotor when the absolute velocities

at inlet and outlet are not equal.

A steam turbine stage of high hub/tip ratio is to receive steam at a stagnation pressure and

temperature of 1.5 MPa and 325 ° C respectively. It is designed for a blade speed of 200 m/s