Page 28 - Fluid Power Engineering

P. 28

Intr oduction to Hydraulic Power Systems 5

1.2.4 Hydrodynamic Power Systems

The hydraulic power systems transmit mechanical power by increas-

ing the energy of hydraulic liquids. Two types of hydraulic power

systems are used: hydrodynamic and hydrostatic.

Hydrodynamic (also called hydrokinetic) power systems transmit

power by increasing mainly the kinetic energy of liquid. Generally, these

systems include a rotodynamic pump, a turbine, and additional control

elements. The applications of hydrodynamic power systems are limited

to rotary motion. These systems replace the classical mechanical trans-

mission in the power stations and vehicles due to their high power-to-

weight ratio and better controllability.

There are two main types of hydrodynamic power systems:

hydraulic coupling and torque converter.

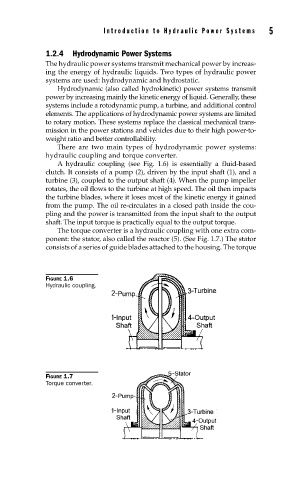

A hydraulic coupling (see Fig. 1.6) is essentially a fluid-based

clutch. It consists of a pump (2), driven by the input shaft (1), and a

turbine (3), coupled to the output shaft (4). When the pump impeller

rotates, the oil flows to the turbine at high speed. The oil then impacts

the turbine blades, where it loses most of the kinetic energy it gained

from the pump. The oil re-circulates in a closed path inside the cou-

pling and the power is transmitted from the input shaft to the output

shaft. The input torque is practically equal to the output torque.

The torque converter is a hydraulic coupling with one extra com-

ponent: the stator, also called the reactor (5). (See Fig. 1.7.) The stator

consists of a series of guide blades attached to the housing. The torque

FIGURE 1.6

Hydraulic coupling.

FIGURE 1.7

Torque converter.