Page 33 - Fluid Power Engineering

P. 33

10 Cha pte r O n e

2. High cost of production due to the requirements of small

clearances and high precision production process.

3. High inertia of transmission lines, which increases their re-

sponse time.

4. Limitation of the maximum and minimum operating tem-

perature.

5. Fire hazard when using mineral oils.

6. Oil filtration problems.

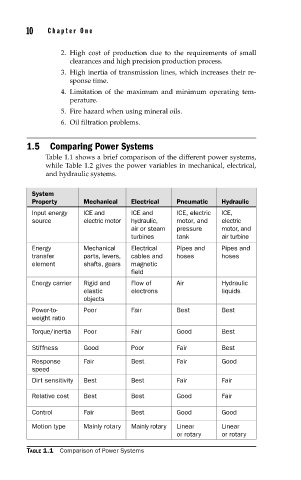

1.5 Comparing Power Systems

Table 1.1 shows a brief comparison of the different power systems,

while Table 1.2 gives the power variables in mechanical, electrical,

and hydraulic systems.

System

Property Mechanical Electrical Pneumatic Hydraulic

Input energy ICE and ICE and ICE, electric ICE,

source electric motor hydraulic, motor, and electric

air or steam pressure motor, and

turbines tank air turbine

Energy Mechanical Electrical Pipes and Pipes and

transfer parts, levers, cables and hoses hoses

element shafts, gears magnetic

field

Energy carrier Rigid and Flow of Air Hydraulic

elastic electrons liquids

objects

Power-to- Poor Fair Best Best

weight ratio

Torque/inertia Poor Fair Good Best

Stiffness Good Poor Fair Best

Response Fair Best Fair Good

speed

Dirt sensitivity Best Best Fair Fair

Relative cost Best Best Good Fair

Control Fair Best Good Good

Motion type Mainly rotary Mainly rotary Linear Linear

or rotary or rotary

TABLE 1.1 Comparison of Power Systems