Page 135 - Fluid mechanics, heat transfer, and mass transfer

P. 135

PUMPS 113

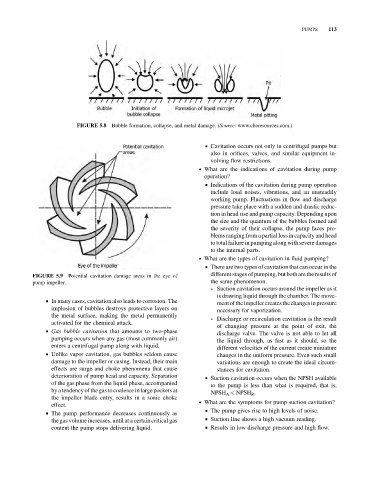

FIGURE 5.8 Bubble formation, collapse, and metal damage. (Source: www.cheresources.com.)

& Cavitation occurs not only in centrifugal pumps but

also in orifices, valves, and similar equipment in-

volving flow restrictions.

. What are the indications of cavitation during pump

operation?

& Indications of the cavitation during pump operation

include loud noises, vibrations, and an unsteadily

working pump. Fluctuations in flow and discharge

pressure take place with a sudden and drastic reduc-

tion in head rise and pump capacity. Depending upon

the size and the quantum of the bubbles formed and

the severity of their collapse, the pump faces pro-

blems ranging from a partial loss in capacity and head

to total failure in pumping along with severe damages

to the internal parts.

. What are the types of cavitation in fluid pumping?

& There are two types of cavitation that can occur in the

FIGURE 5.9 Potential cavitation damage areas in the eye of different stages of pumping, butboth are the results of

pump impeller. the same phenomenon.

➢ Suction cavitation occurs around the impeller as it

is drawing liquid through the chamber. The move-

& In many cases, cavitation also leads to corrosion. The

mentoftheimpellercreatesthechangesinpressure

implosion of bubbles destroys protective layers on necessary for vaporization.

the metal surface, making the metal permanently

➢ Discharge or recirculation cavitation is the result

activated for the chemical attack.

of changing pressure at the point of exit, the

& Gas bubble cavitation that amounts to two-phase

discharge valve. The valve is not able to let all

pumping occurs when any gas (most commonly air) the liquid through, as fast as it should, so the

enters a centrifugal pump along with liquid. different velocities of the current create miniature

& Unlike vapor cavitation, gas bubbles seldom cause changes in the uniform pressure. Even such small

damage to the impeller or casing. Instead, their main variations are enough to create the ideal circum-

effects are surge and choke phenomena that cause stances for cavitation.

deterioration of pump head and capacity. Separation & Suction cavitation occurs when the NPSH available

of the gas phase from the liquid phase, accompanied

to the pump is less than what is required, that is,

byatendencyof thegas to coalesce in largepockets at

NPSH A < NPSH R .

the impeller blade entry, results in a sonic choke

. What are the symptoms for pump suction cavitation?

effect.

& The pump gives rise to high levels of noise.

& The pump performance decreases continuously as

the gas volume increases, until at a certain critical gas & Suction line shows a high vacuum reading.

content the pump stops delivering liquid. & Results in low discharge pressure and high flow.