Page 138 - Fluid mechanics, heat transfer, and mass transfer

P. 138

116 PUMPS, EJECTORS, BLOWERS, AND COMPRESSORS

& Sources for air/gas can be release of dissolved gas,

formation of slugs by entrained gas or through va-

porization of the liquid.

& Vaporization. Vaporization in the suction line can

also cause vapor lock. If the vapor formed is 10% or

more, vapor lock can occur.

➢ Vapor formation can be avoided by increasing

pressure through increase in level in the supply

tank, reducing frictional losses in suction line

through use of larger pipe diameters and minimum

number of fittings, valves, and so on, decreasing

liquid temperature by cooling or using a pump

with a lower NPSH R .

. Explain how pump capacity reduces if cavitation is

occurring.

& The formation of bubbles causes a volume increase,

decreasing the space available in the pump casing for

the liquid and thus diminishes pumping capacity. For

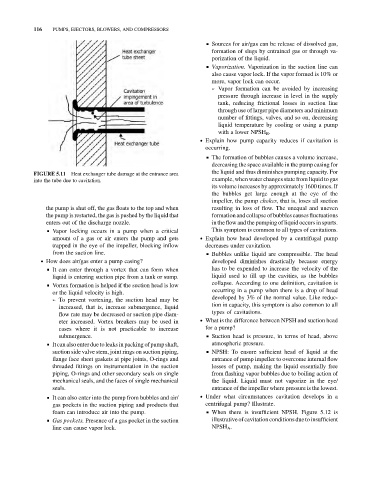

FIGURE 5.11 Heat exchanger tube damage at the entrance area

into the tube due to cavitation. example, when water changes state from liquid to gas

its volume increases by approximately 1600 times. If

the bubbles get large enough at the eye of the

impeller, the pump chokes, that is, loses all suction

the pump is shut off, the gas floats to the top and when resulting in loss of flow. The unequal and uneven

the pump is restarted, the gas is pushed by the liquid that formation and collapse of bubbles causes fluctuations

enters out of the discharge nozzle. in the flow and the pumping of liquid occurs in spurts.

& Vapor locking occurs in a pump when a critical This symptom is common to all types of cavitations.

amount of a gas or air enters the pump and gets . Explain how head developed by a centrifugal pump

trapped in the eye of the impeller, blocking inflow decreases under cavitation.

from the suction line. & Bubbles unlike liquid are compressible. The head

. How does air/gas enter a pump casing? developed diminishes drastically because energy

& It can enter through a vortex that can form when has to be expended to increase the velocity of the

liquid is entering suction pipe from a tank or sump. liquid used to fill up the cavities, as the bubbles

collapse. According to one definition, cavitation is

& Vortex formation is helped if the suction head is low

occurring in a pump when there is a drop of head

or the liquid velocity is high.

developed by 3% of the normal value. Like reduc-

➢ To prevent vortexing, the suction head may be

tion in capacity, this symptom is also common to all

increased, that is, increase submergence, liquid

types of cavitations.

flow rate may be decreased or suction pipe diam-

eter increased. Vortex breakers may be used in . What is the difference between NPSH and suction head

cases where it is not practicable to increase for a pump?

submergence. & Suction head is pressure, in terms of head, above

& It can also enter due to leaks in packing of pump shaft, atmospheric pressure.

suction side valve stem, joint rings on suction piping, & NPSH: To ensure sufficient head of liquid at the

flange face sheet gaskets at pipe joints, O-rings and entrance of pump impeller to overcome internal flow

threaded fittings on instrumentation in the suction losses of pump, making the liquid essentially free

piping, O-rings and other secondary seals on single from flashing vapor bubbles due to boiling action of

mechanical seals, and the faces of single mechanical the liquid. Liquid must not vaporize in the eye/

seals. entrance of the impeller where pressure is the lowest.

& It can also enter into the pump from bubbles and air/ . Under what circumstances cavitation develops in a

gas pockets in the suction piping and products that centrifugal pump? Illustrate.

foam can introduce air into the pump. & When there is insufficient NPSH. Figure 5.12 is

& Gas pockets. Presence of a gas pocket in the suction illustrativeof cavitation conditions due to insufficient

line can cause vapor lock. NPSH A .