Page 40 - Fluid mechanics, heat transfer, and mass transfer

P. 40

FLUID STATICS 17

device. The higher the liquid density, the smaller

the paddle required.

➢ The cost-effective and low-maintenance electro-

mechanical designs are well suited for solids such

as plastic pellets, carbon black, fertilizers, Styro-

foam, and rubber chips and beads.

➢ The paddle switch can handle bulk densities as

low as 35 g/L and the technology is completely

independentof dielectric properties of thematerial.

& Capacitance: A capacitance probe can be immersed

in the liquid in the tank and the capacitance between

the probe and thevessel wall depends on the level. By

measuring the capacitance of the liquid, the level in

the tank can be determined. Capacitance can be

affected by density variations.

➢ Capacitance technology is widely used in many

industries and can handle a wide range of applica-

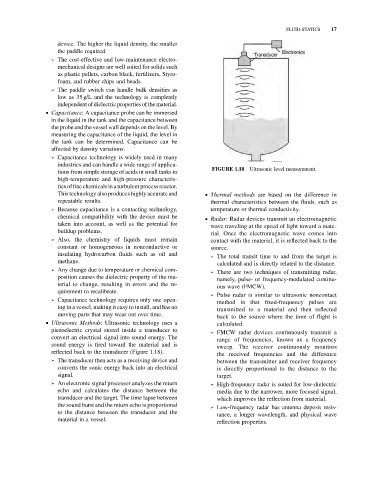

FIGURE 1.18 Ultrasonic level measurement.

tions from simple storage of acids in small tanks to

high-temperature and high-pressure characteris-

tics offine chemicals in a turbulent process reactor.

This technology also produces highly accurate and & Thermal methods are based on the difference in

repeatable results. thermal characteristics between the fluids, such as

➢ Because capacitance is a contacting technology, temperature or thermal conductivity.

chemical compatibility with the device must be & Radar: Radar devices transmit an electromagnetic

taken into account, as well as the potential for

wave traveling at the speed of light toward a mate-

buildup problems.

rial. Once the electromagnetic wave comes into

➢ Also, the chemistry of liquids must remain contact with the material, it is reflected back to the

constant or homogeneous in nonconductive or source.

insulating hydrocarbon fluids such as oil and

➢ The total transit time to and from the target is

methane.

calculated and is directly related to the distance.

➢ Any change due to temperature or chemical com- ➢ There are two techniques of transmitting radar,

position causes the dielectric property of the ma-

namely, pulse- or frequency-modulated continu-

terial to change, resulting in errors and the re-

ous wave (FMCW).

quirement to recalibrate.

➢ Pulse radar is similar to ultrasonic noncontact

➢ Capacitance technology requires only one open-

method in that fixed-frequency pulses are

ing in a vessel, making it easy to install, and has no

transmitted to a material and then reflected

moving parts that may wear out over time.

back to the source where the time of flight is

& Ultrasonic Methods: Ultrasonic technology uses a

calculated.

piezoelectric crystal stored inside a transducer to ➢ FMCW radar devices continuously transmit a

convert an electrical signal into sound energy. The

range of frequencies, known as a frequency

sound energy is fired toward the material and is sweep. The receiver continuously monitors

reflected back to the transducer (Figure 1.18). the received frequencies and the difference

➢ The transducer then acts as a receiving device and between the transmitter and receiver frequency

converts the sonic energy back into an electrical is directly proportional to the distance to the

signal. target.

➢ An electronic signal processor analyzes the return ➢ High-frequency radar is suited for low-dielectric

echo and calculates the distance between the media due to the narrower, more focused signal,

transducer and the target. The time lapse between which improves the reflection from material.

the sound burst and the return echo is proportional

➢ Low-frequency radar has antenna deposit resis-

to the distance between the transducer and the

tance, a longer wavelength, and physical wave

material in a vessel.

reflection properties.