Page 42 - Fluid mechanics, heat transfer, and mass transfer

P. 42

FLUID STATICS 19

TABLE 1.3 Modern Level Measuring Methods and Their

Applications

Method Applications

Electromechanical Plastic pellets, Styrofoam beads and

chips, carbon black, fertilizers

Capacitance Acids, alkalis, styrene and other

aromatics, adhesives, and so on

Ultrasonic Chemical storage tanks, wastewater

effluents, plastic pellets

Radar Bulk storage vessels for chemicals,

agitated and reaction process vessels,

sulfur storage

Guided wave radar Liquids and slurries, plastic pellets,

displacer replacement

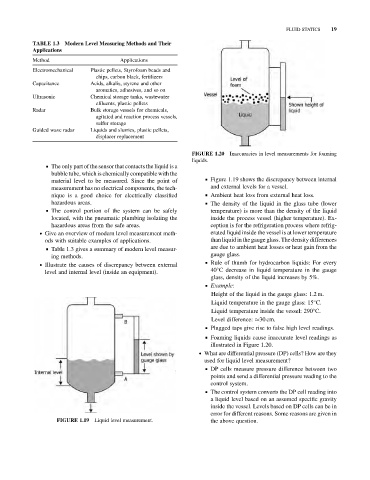

FIGURE 1.20 Inaccuracies in level measurements for foaming

liquids.

& The only part of the sensor that contacts the liquid is a

bubble tube, which is chemically compatible with the

& Figure 1.19 shows the discrepancy between internal

material level to be measured. Since the point of

measurement has no electrical components, the tech- and external levels for a vessel.

nique is a good choice for electrically classified & Ambient heat loss from external heat loss.

hazardous areas. & The density of the liquid in the glass tube (lower

& The control portion of the system can be safely temperature) is more than the density of the liquid

located, with the pneumatic plumbing isolating the inside the process vessel (higher temperature). Ex-

hazardous areas from the safe areas. ception is for the refrigeration process where refrig-

. Give an overview of modern level measurement meth- erated liquid inside the vessel is at lower temperature

ods with suitable examples of applications. than liquid in thegauge glass. The density differences

& Table 1.3 gives a summary of modern level measur- are due to ambient heat losses or heat gain from the

ing methods. gauge glass.

& Rule of thumb for hydrocarbon liquids: For every

. Illustrate the causes of discrepancy between external

level and internal level (inside an equipment). 40 C decrease in liquid temperature in the gauge

glass, density of the liquid increases by 5%.

& Example:

Height of the liquid in the gauge glass: 1.2 m.

Liquid temperature in the gauge glass: 15 C.

Liquid temperature inside the vessel: 290 C.

Level difference: 30 cm.

& Plugged taps give rise to false high level readings.

& Foaming liquids cause inaccurate level readings as

illustrated in Figure 1.20.

. What are differential pressure (DP) cells? How are they

used for liquid level measurement?

& DP cells measure pressure difference between two

points and send a differential pressure reading to the

control system.

& The control system converts the DP cell reading into

a liquid level based on an assumed specific gravity

inside the vessel. Levels based on DP cells can be in

error for different reasons. Some reasons are given in

FIGURE 1.19 Liquid level measurement. the above question.