Page 301 - Forensic Structural Engineering Handbook

P. 301

9.12 CAUSES OF FAILURES

Not every component within a structure is designed to last as long as the structure itself.

Economic factors and design constraints dictate that some components and materials act as

sacrificial elements (e.g., zinc coatings); some are exposed to more severe weathering (e.g.,

roofing); and some cannot be manufactured at a reasonable cost to last long-term (e.g., paint).

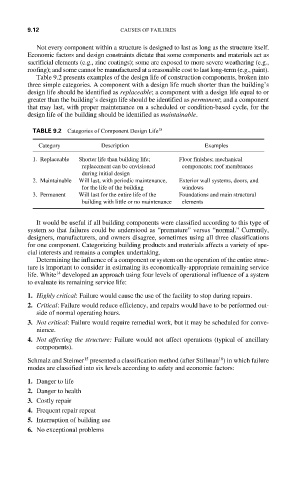

Table 9.2 presents examples of the design life of construction components, broken into

three simple categories. A component with a design life much shorter than the building’s

design life should be identified as replaceable; a component with a design life equal to or

greater than the building’s design life should be identified as permanent; and a component

that may last, with proper maintenance on a scheduled or condition-based cycle, for the

design life of the building should be identified as maintainable.

TABLE 9.2 Categories of Component Design Life 18

Category Description Examples

1. Replaceable Shorter life than building life; Floor finishes; mechanical

replacement can be envisioned components; roof membranes

during initial design

2. Maintainable Will last, with periodic maintenance, Exterior wall systems, doors, and

for the life of the building windows

3. Permanent Will last for the entire life of the Foundations and main structural

building with little or no maintenance elements

It would be useful if all building components were classified according to this type of

system so that failures could be understood as “premature” versus “normal.” Currently,

designers, manufacturers, and owners disagree, sometimes using all three classifications

for one component. Categorizing building products and materials affects a variety of spe-

cial interests and remains a complex undertaking.

Determining the influence of a component or system on the operation of the entire struc-

ture is important to consider in estimating its economically-appropriate remaining service

14

life. White developed an approach using four levels of operational influence of a system

to evaluate its remaining service life:

1. Highly critical: Failure would cause the use of the facility to stop during repairs.

2. Critical: Failure would reduce efficiency, and repairs would have to be performed out-

side of normal operating hours.

3. Not critical: Failure would require remedial work, but it may be scheduled for conve-

nience.

4. Not affecting the structure: Failure would not affect operations (typical of ancillary

components).

15

16

Schmalz and Steimer presented a classification method (after Stillman ) in which failure

modes are classified into six levels according to safety and economic factors:

1. Danger to life

2. Danger to health

3. Costly repair

4. Frequent repair repeat

5. Interruption of building use

6. No exceptional problems