Page 399 - Forensic Structural Engineering Handbook

P. 399

11.30 MATERIAL-SPECIFIC FORENSIC ANALYSES

Purlin Edge

beam

15' 15'

Post

30' 30'

Negligible

brace

Top

Assumed

No brace brace chord

Out of plane

component Buckling Axis of Buckling

shape

of load

Load In plane intermediate shape

diagonal

component

of load Intermediate

diagonal

FIGURE 11.12 Lateral support connection of top chord at mid-length.

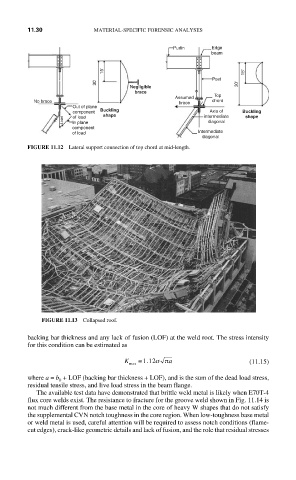

FIGURE 11.13 Collapsed roof.

backing bar thickness and any lack of fusion (LOF) at the weld root. The stress intensity

for this condition can be estimated as

K ≅ . 112σπ a (11.15)

max

where a = b + LOF (backing bar thickness + LOF), and is the sum of the dead load stress,

b

residual tensile stress, and live load stress in the beam flange.

The available test data have demonstrated that brittle weld metal is likely when E70T-4

flux core welds exist. The resistance to fracture for the groove weld shown in Fig. 11.14 is

not much different from the base metal in the core of heavy W shapes that do not satisfy

the supplemental CVN notch toughness in the core region. When low-toughness base metal

or weld metal is used, careful attention will be required to assess notch conditions (flame-

cut edges), crack-like geometric details and lack of fusion, and the role that residual stresses