Page 400 - Forensic Structural Engineering Handbook

P. 400

STEEL STRUCTURES 11.31

Continuity

plates

Typ

Backing bar

detail

(a)

(b)

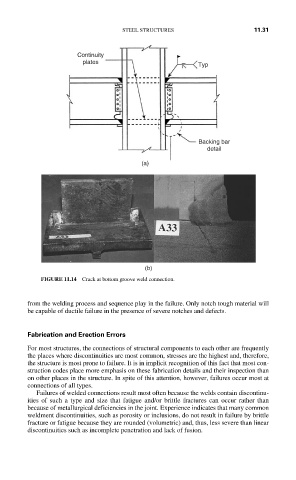

FIGURE 11.14 Crack at bottom groove weld connection.

from the welding process and sequence play in the failure. Only notch tough material will

be capable of ductile failure in the presence of severe notches and defects.

Fabrication and Erection Errors

For most structures, the connections of structural components to each other are frequently

the places where discontinuities are most common, stresses are the highest and, therefore,

the structure is most prone to failure. It is in implicit recognition of this fact that most con-

struction codes place more emphasis on these fabrication details and their inspection than

on other places in the structure. In spite of this attention, however, failures occur most at

connections of all types.

Failures of welded connections result most often because the welds contain discontinu-

ities of such a type and size that fatigue and/or brittle fractures can occur rather than

because of metallurgical deficiencies in the joint. Experience indicates that many common

weldment discontinuities, such as porosity or inclusions, do not result in failure by brittle

fracture or fatigue because they are rounded (volumetric) and, thus, less severe than linear

discontinuities such as incomplete penetration and lack of fusion.