Page 339 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 339

Be st Practice 5 .14 Steam Turbine Best Practices

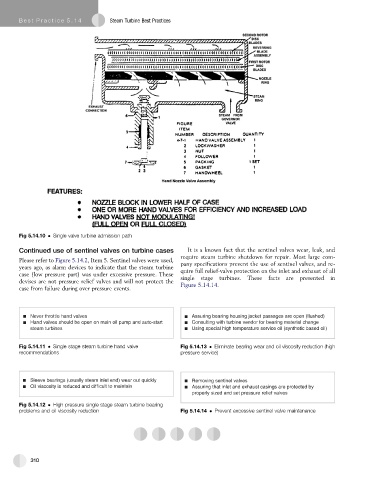

Fig 5.14.10 Single valve turbine admission path

Continued use of sentinel valves on turbine cases It is a known fact that the sentinel valves wear, leak, and

require steam turbine shutdown for repair. Most large com-

Please refer to Figure 5.14.2, Item 5. Sentinel valves were used,

years ago, as alarm devices to indicate that the steam turbine pany specifications prevent the use of sentinel valves, and re-

quire full relief-valve protection on the inlet and exhaust of all

case (low pressure part) was under excessive pressure. These

devises are not pressure relief valves and will not protect the single stage turbines. These facts are presented in

Figure 5.14.14.

case from failure during over pressure events.

Never throttle hand valves Assuring bearing housing jacket passages are open (flushed)

Hand valves should be open on main oil pump and auto-start Consulting with turbine vendor for bearing material change

steam turbines Using special high temperature service oil (synthetic based oil)

Fig 5.14.11 Single stage steam turbine hand valve Fig 5.14.13 Eliminate bearing wear and oil viscosity reduction (high

recommendations pressure service)

Sleeve bearings (usually steam inlet end) wear out quickly Removing sentinel valves

Oil viscosity is reduced and difficult to maintain Assuring that inlet and exhaust casings are protected by

properly sized and set pressure relief valves

Fig 5.14.12 High pressure single stage steam turbine bearing

problems and oil viscosity reduction Fig 5.14.14 Prevent excessive sentinel valve maintenance

310