Page 611 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 611

Implementation and Communication Best Practices Best Practice 1 2.4

B.P. 12.4. Supporting Material A detailed workshop report is issued no later than two weeks

after site presentation and contains the following information:

Contained in this section are two agendas from the most popular

site-specific workshops we have presented since 1990: - Attendee evaluation results of the workshop

- Instructor evaluation of the attendees

- Principles of Rotating Machinery - Specific instructor evaluation of the understanding of each

- Machinery Reliability Optimization presented principle (Training Module) and

recommendations to ensure implementation

All of our workshops are structured on existing site reliability - Recommendations for Continuous Improvement based on

issues, include site-specific machinery documents (secrecy issues raised by the attendees and discussed during the

agreements signed) and site visits to ensure implementation of workshop

the learned principles.

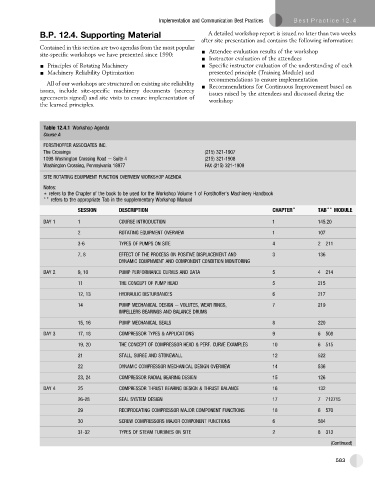

Table 12.4.1 Workshop Agenda

Course A

FORSTHOFFER ASSOCIATES INC.

The Crossings (215) 321-1907

1098 Washington Crossing Road e Suite 4 (215) 321-1908

Washington Crossing, Pennsylvania 18977 FAX (215) 321-1909

SITE ROTATING EQUIPMENT FUNCTION OVERVIEW WORKSHOP AGENDA

Notes:

) refers to the Chapter of the book to be used for the Workshop Volume 1 of Forsthoffer's Machinery Handbook

)) refers to the appropriate Tab in the supplementary Workshop Manual

SESSION DESCRIPTION CHAPTER ) TAB )) MODULE

DAY 1 1 COURSE INTRODUCTION 1 145.20

2 ROTATING EQUIPMENT OVERVIEW 1 107

3-6 TYPES OF PUMPS ON SITE 4 2 211

7, 8 EFFECT OF THE PROCESS ON POSITIVE DISPLACEMENT AND 3 136

DYNAMIC EQUIPNMENT AND COMPONENT CONDITION MONITORING

DAY 2 9, 10 PUMP PERFORMANCE CURVES AND DATA 5 4 214

11 THE CONCEPT OF PUMP HEAD 5 215

12, 13 HYDRAULIC DISTURBANCES 6 217

14 PUMP MECHANICAL DESIGN e VOLUTES, WEAR RINGS, 7 219

IMPELLERS BEARINGS AND BALANCE DRUMS

15, 16 PUMP MECHANICAL SEALS 8 220

DAY 3 17, 18 COMPRESSOR TYPES & APPLICATIONS 9 6 508

19, 20 THE CONCEPT OF COMPRESSOR HEAD & PERF. CURVE EXAMPLES 10 6 515

21 STALL, SURGE AND STONEWALL 12 522

22 DYNAMIC COMPRESSOR MECHANICAL DESIGN OVERVIEW 14 536

23, 24 COMPRESSOR RADIAL BEARING DESIGN 15 126

DAY 4 25 COMPRESSOR THRUST BEARING DESIGN & THRUST BALANCE 16 132

26-28 SEAL SYSTEM DESIGN 17 7 712715

29 RECIPROCATING COMPRESSOR MAJOR COMPONENT FUNCTIONS 18 6 570

30 SCREW COMPRESSORS MAJOR COMPONENT FUNCTIONS 6 584

31-32 TYPES OF STEAM TURBINES ON SITE 2 8 313

(Continued)

583