Page 26 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 26

1656_C01.fm Page 6 Tuesday, April 12, 2005 5:55 PM

6 Fracture Mechanics: Fundamentals and Applications

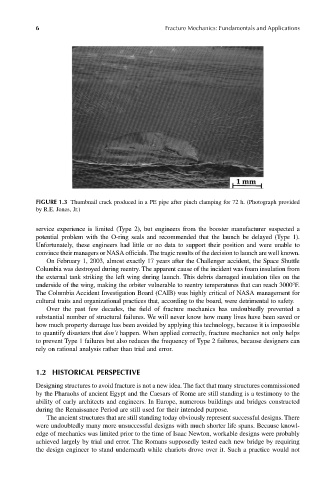

FIGURE 1.3 Thumbnail crack produced in a PE pipe after pinch clamping for 72 h. (Photograph provided

by R.E. Jones, Jr.)

service experience is limited (Type 2), but engineers from the booster manufacturer suspected a

potential problem with the O-ring seals and recommended that the launch be delayed (Type 1).

Unfortunately, these engineers had little or no data to support their position and were unable to

convince their managers or NASA officials. The tragic results of the decision to launch are well known.

On February 1, 2003, almost exactly 17 years after the Challenger accident, the Space Shuttle

Columbia was destroyed during reentry. The apparent cause of the incident was foam insulation from

the external tank striking the left wing during launch. This debris damaged insulation tiles on the

underside of the wing, making the orbiter vulnerable to reentry temperatures that can reach 3000°F.

The Columbia Accident Investigation Board (CAIB) was highly critical of NASA management for

cultural traits and organizational practices that, according to the board, were detrimental to safety.

Over the past few decades, the field of fracture mechanics has undoubtedly prevented a

substantial number of structural failures. We will never know how many lives have been saved or

how much property damage has been avoided by applying this technology, because it is impossible

to quantify disasters that don’t happen. When applied correctly, fracture mechanics not only helps

to prevent Type 1 failures but also reduces the frequency of Type 2 failures, because designers can

rely on rational analysis rather than trial and error.

1.2 HISTORICAL PERSPECTIVE

Designing structures to avoid fracture is not a new idea. The fact that many structures commissioned

by the Pharaohs of ancient Egypt and the Caesars of Rome are still standing is a testimony to the

ability of early architects and engineers. In Europe, numerous buildings and bridges constructed

during the Renaissance Period are still used for their intended purpose.

The ancient structures that are still standing today obviously represent successful designs. There

were undoubtedly many more unsuccessful designs with much shorter life spans. Because knowl-

edge of mechanics was limited prior to the time of Isaac Newton, workable designs were probably

achieved largely by trial and error. The Romans supposedly tested each new bridge by requiring

the design engineer to stand underneath while chariots drove over it. Such a practice would not