Page 27 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 27

1656_C01.fm Page 7 Tuesday, April 12, 2005 5:55 PM

History and Overview 7

only provide an incentive for developing good designs, but would also result in the social equivalent

of Darwinian natural selection, where the worst engineers were removed from the profession.

The durability of ancient structures is particularly amazing when one considers that the choice

of building materials prior to the Industrial Revolution was rather limited. Metals could not be

produced in sufficient quantity to be formed into load-bearing members for buildings and bridges.

The primary construction materials prior to the 19th century were timber, brick, and mortar; only

the latter two materials were usually practical for large structures such as cathedrals, because trees

of sufficient size for support beams were rare.

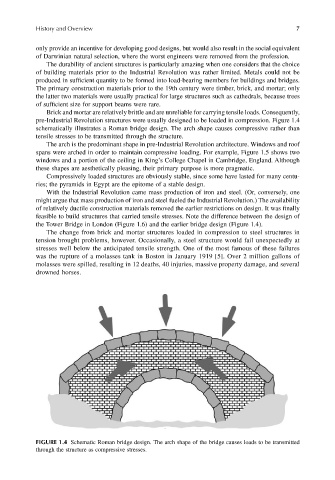

Brick and mortar are relatively brittle and are unreliable for carrying tensile loads. Consequently,

pre-Industrial Revolution structures were usually designed to be loaded in compression. Figure 1.4

schematically illustrates a Roman bridge design. The arch shape causes compressive rather than

tensile stresses to be transmitted through the structure.

The arch is the predominant shape in pre-Industrial Revolution architecture. Windows and roof

spans were arched in order to maintain compressive loading. For example, Figure 1.5 shows two

windows and a portion of the ceiling in King’s College Chapel in Cambridge, England. Although

these shapes are aesthetically pleasing, their primary purpose is more pragmatic.

Compressively loaded structures are obviously stable, since some have lasted for many centu-

ries; the pyramids in Egypt are the epitome of a stable design.

With the Industrial Revolution came mass production of iron and steel. (Or, conversely, one

might argue that mass production of iron and steel fueled the Industrial Revolution.) The availability

of relatively ductile construction materials removed the earlier restrictions on design. It was finally

feasible to build structures that carried tensile stresses. Note the difference between the design of

the Tower Bridge in London (Figure 1.6) and the earlier bridge design (Figure 1.4).

The change from brick and mortar structures loaded in compression to steel structures in

tension brought problems, however. Occasionally, a steel structure would fail unexpectedly at

stresses well below the anticipated tensile strength. One of the most famous of these failures

was the rupture of a molasses tank in Boston in January 1919 [5]. Over 2 million gallons of

molasses were spilled, resulting in 12 deaths, 40 injuries, massive property damage, and several

drowned horses.

FIGURE 1.4 Schematic Roman bridge design. The arch shape of the bridge causes loads to be transmitted

through the structure as compressive stresses.