Page 269 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 269

1656_C005.fm Page 249 Monday, May 23, 2005 5:47 PM

Fracture Mechanisms in Metals 249

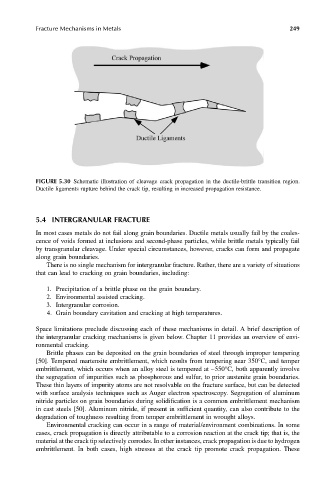

FIGURE 5.30 Schematic illustration of cleavage crack propagation in the ductile-brittle transition region.

Ductile ligaments rupture behind the crack tip, resulting in increased propagation resistance.

5.4 INTERGRANULAR FRACTURE

In most cases metals do not fail along grain boundaries. Ductile metals usually fail by the coales-

cence of voids formed at inclusions and second-phase particles, while brittle metals typically fail

by transgranular cleavage. Under special circumstances, however, cracks can form and propagate

along grain boundaries.

There is no single mechanism for intergranular fracture. Rather, there are a variety of situations

that can lead to cracking on grain boundaries, including:

1. Precipitation of a brittle phase on the grain boundary.

2. Environmental assisted cracking.

3. Intergranular corrosion.

4. Grain boundary cavitation and cracking at high temperatures.

Space limitations preclude discussing each of these mechanisms in detail. A brief description of

the intergranular cracking mechanisms is given below. Chapter 11 provides an overview of envi-

ronmental cracking.

Brittle phases can be deposited on the grain boundaries of steel through improper tempering

[50]. Tempered martensite embrittlement, which results from tempering near 350°C, and temper

embrittlement, which occurs when an alloy steel is tempered at ∼550°C, both apparently involve

the segregation of impurities such as phosphorous and sulfur, to prior austenite grain boundaries.

These thin layers of impurity atoms are not resolvable on the fracture surface, but can be detected

with surface analysis techniques such as Auger electron spectroscopy. Segregation of aluminum

nitride particles on grain boundaries during solidification is a common embrittlement mechanism

in cast steels [50]. Aluminum nitride, if present in sufficient quantity, can also contribute to the

degradation of toughness resulting from temper embrittlement in wrought alloys.

Environmental cracking can occur in a range of material/environment combinations. In some

cases, crack propagation is directly attributable to a corrosion reaction at the crack tip; that is, the

material at the crack tip selectively corrodes. In other instances, crack propagation is due to hydrogen

embrittlement. In both cases, high stresses at the crack tip promote crack propagation. These