Page 267 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 267

1656_C005.fm Page 247 Monday, May 23, 2005 5:47 PM

Fracture Mechanisms in Metals 247

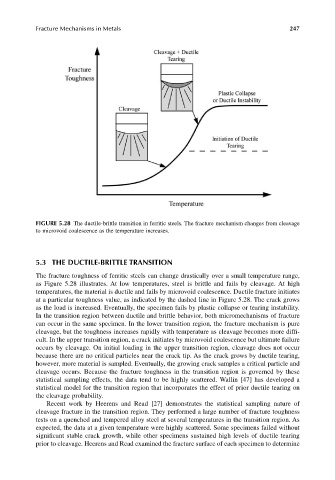

FIGURE 5.28 The ductile-brittle transition in ferritic steels. The fracture mechanism changes from cleavage

to microvoid coalescence as the temperature increases.

5.3 THE DUCTILE-BRITTLE TRANSITION

The fracture toughness of ferritic steels can change drastically over a small temperature range,

as Figure 5.28 illustrates. At low temperatures, steel is brittle and fails by cleavage. At high

temperatures, the material is ductile and fails by microvoid coalescence. Ductile fracture initiates

at a particular toughness value, as indicated by the dashed line in Figure 5.28. The crack grows

as the load is increased. Eventually, the specimen fails by plastic collapse or tearing instability.

In the transition region between ductile and brittle behavior, both micromechanisms of fracture

can occur in the same specimen. In the lower transition region, the fracture mechanism is pure

cleavage, but the toughness increases rapidly with temperature as cleavage becomes more diffi-

cult. In the upper transition region, a crack initiates by microvoid coalescence but ultimate failure

occurs by cleavage. On initial loading in the upper transition region, cleavage does not occur

because there are no critical particles near the crack tip. As the crack grows by ductile tearing,

however, more material is sampled. Eventually, the growing crack samples a critical particle and

cleavage occurs. Because the fracture toughness in the transition region is governed by these

statistical sampling effects, the data tend to be highly scattered. Wallin [47] has developed a

statistical model for the transition region that incorporates the effect of prior ductile tearing on

the cleavage probability.

Recent work by Heerens and Read [27] demonstrates the statistical sampling nature of

cleavage fracture in the transition region. They performed a large number of fracture toughness

tests on a quenched and tempered alloy steel at several temperatures in the transition region. As

expected, the data at a given temperature were highly scattered. Some specimens failed without

significant stable crack growth, while other specimens sustained high levels of ductile tearing

prior to cleavage. Heerens and Read examined the fracture surface of each specimen to determine