Page 302 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 302

1656_C006.fm Page 282 Monday, May 23, 2005 5:50 PM

282 Fracture Mechanics: Fundamentals and Applications

6.2 CERAMICS AND CERAMIC COMPOSITES

A number of technological initiatives have been proposed whose implementation depends on achieving

major advances in materials technology. For example, the National Aerospace Plane will re-enter the

earth’s atmosphere at speeds of up to Mach 25, creating extremes of both temperature and stress. Also,

the Advanced Turbine Technology Applications Program (ATTAP) has the stated goal of developing

heat engines that have a service life of 3000 h at 1350°C. Additional applications are on the horizon

that will require materials that can perform at temperatures in excess of 2000°C. All metals, including

cobalt-based superalloys, are inadequate at these temperatures. Only ceramics possess adequate creep

resistance above 1000°C.

Ceramic materials include oxides, carbides, sulfides, and intermetallic compounds, which are

joined either by covalent or ionic bonds. Most ceramics are crystalline but, unlike metals, they do

not have close-packed planes on which dislocation motion can occur. Therefore, ceramic materials

tend to be very brittle compared to metals.

Typical ceramics have very high melting temperatures, which explains their good creep prop-

erties. Also, many of these materials have superior wear resistance, and have been used for bearings

and machine tools. Most ceramics, however, are too brittle for critical load-bearing applications.

Consequently, a vast amount of research has been devoted to improving the toughness of ceramics.

Most traditional ceramics are monolithic (single phase) and have very low fracture toughness.

Because they do not yield, monolithic ceramics behave as ideally brittle materials (Figure 2.6(a)),

and a propagating crack need only overcome the surface energy of the material. The new generation

of ceramics, however, includes multiphase materials and ceramic composites that have vastly

improved toughness. Under certain conditions, two brittle solids can be combined to produce a

material that is significantly tougher than either parent material.

The micromechanisms that lead to improved fracture resistance in modern ceramics include

microcrack toughening, transformation toughening, ductile phase toughening, fiber toughening, and

whisker toughening. Table 6.1 lists the dominant toughening mechanism in several materials, along

with the typical fracture toughness values [40]. Fiber toughening, the most effective mechanism,

produces toughness values around 20 MPa m , which is below the lower shelf toughness of steels

but is significantly higher than most ceramics.

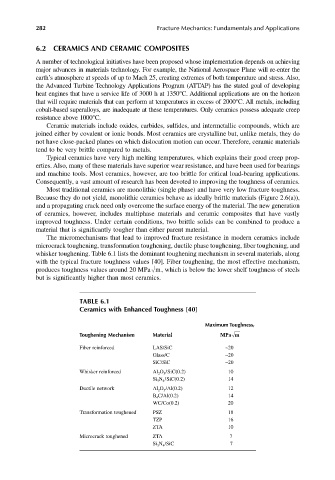

TABLE 6.1

Ceramics with Enhanced Toughness [40]

Maximum Toughness,

Toughening Mechanism Material MPa m

Fiber reinforced LAS/SiC ~20

Glass/C ~20

SiC/SiC ~20

Whisker reinforced Al 2 O 3 /SiC(0.2) 10

Si 3 N 4 /SiC(0.2) 14

Ductile network Al 2 O 3 /Al(0.2) 12

B 4 C/Al(0.2) 14

WC/Co(0.2) 20

Transformation toughened PSZ 18

TZP 16

ZTA 10

Microcrack toughened ZTA 7

Si 3 N 4 /SiC 7