Page 297 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 297

1656_C006.fm Page 277 Monday, May 23, 2005 5:50 PM

Fracture Mechanisms in Nonmetals 277

FIGURE 6.20 Compressive loading of a column that

is supported laterally by an elastic foundation.

An additional complication in real composites is fiber waviness. Fibers are seldom perfectly

straight; rather they tend to have a sine wave-like profile, as Figure 6.22 illustrates [30]. Such a

configuration is less stable in compression than a straight column.

Recent investigators [30–32] have incorporated the effects of matrix nonlinearity and fiber waviness

into failure models. Most failure models are based on continuum theory and thus do not address the

localized nature of microbuckling. Guynn [32], however, has performed detailed numerical simulations

of compression loading of fibers in a nonlinear matrix.

Microbuckling is not the only mechanism for compressive failure. Figure 6.15(d) illustrates

buckling delamination, which is a macroscopic instability. This type of failure is common in com-

posites that have been subject to impact damage, which produces microcracks and delamination

flaws in the material. Delamination buckling induces Mode I loading, which causes the delamination

flaw to propagate at sufficiently high loads. This delamination growth can be characterized with

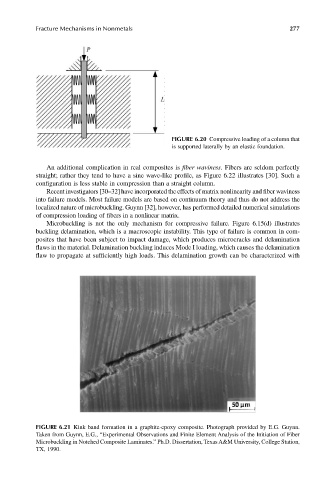

FIGURE 6.21 Kink band formation in a graphite-epoxy composite. Photograph provided by E.G. Guynn.

Taken from Guynn, E.G., “Experimental Observations and Finite Element Analysis of the Initiation of Fiber

Microbuckling in Notched Composite Laminates.” Ph.D. Dissertation, Texas A&M University, College Station,

TX, 1990.