Page 293 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 293

1656_C006.fm Page 273 Monday, May 23, 2005 5:50 PM

Fracture Mechanisms in Nonmetals 273

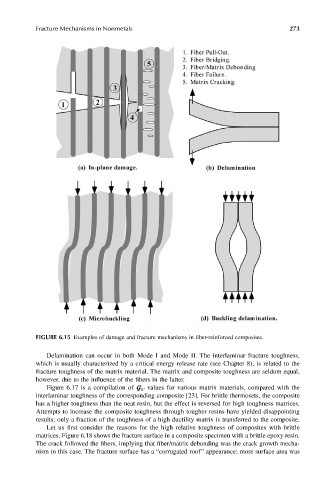

FIGURE 6.15 Examples of damage and fracture mechanisms in fiber-reinforced composites.

Delamination can occur in both Mode I and Mode II. The interlaminar fracture toughness,

which is usually characterized by a critical energy release rate (see Chapter 8), is related to the

fracture toughness of the matrix material. The matrix and composite toughness are seldom equal,

however, due to the influence of the fibers in the latter.

Figure 6.17 is a compilation of G values for various matrix materials, compared with the

IC

interlaminar toughness of the corresponding composite [23]. For brittle thermosets, the composite

has a higher toughness than the neat resin, but the effect is reversed for high toughness matrices.

Attempts to increase the composite toughness through tougher resins have yielded disappointing

results; only a fraction of the toughness of a high ductility matrix is transferred to the composite.

Let us first consider the reasons for the high relative toughness of composites with brittle

matrices. Figure 6.18 shows the fracture surface in a composite specimen with a brittle epoxy resin.

The crack followed the fibers, implying that fiber/matrix debonding was the crack growth mecha-

nism in this case. The fracture surface has a “corrugated roof” appearance; more surface area was