Page 304 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 304

1656_C006.fm Page 284 Monday, May 23, 2005 5:50 PM

284 Fracture Mechanics: Fundamentals and Applications

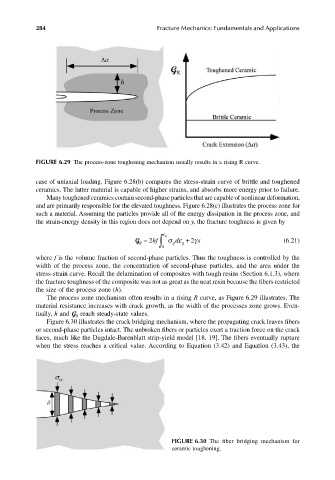

FIGURE 6.29 The process-zone toughening mechanism usually results in a rising R curve.

case of uniaxial loading. Figure 6.28(b) compares the stress-strain curve of brittle and toughened

ceramics. The latter material is capable of higher strains, and absorbs more energy prior to failure.

Many toughened ceramics contain second-phase particles that are capable of nonlinear deformation,

and are primarily responsible for the elevated toughness. Figure 6.28(c) illustrates the process zone for

such a material. Assuming the particles provide all of the energy dissipation in the process zone, and

the strain-energy density in this region does not depend on y, the fracture toughness is given by

d

G = R hf ∫ ij ε σε i j + 2 2γ s (6.21)

i

j

0

where f is the volume fraction of second-phase particles. Thus the toughness is controlled by the

width of the process zone, the concentration of second-phase particles, and the area under the

stress-strain curve. Recall the delamination of composites with tough resins (Section 6.1.3), where

the fracture toughness of the composite was not as great as the neat resin because the fibers restricted

the size of the process zone (h).

The process zone mechanism often results in a rising R curve, as Figure 6.29 illustrates. The

material resistance increases with crack growth, as the width of the processes zone grows. Even-

tually, h and G reach steady-state values.

R

Figure 6.30 illustrates the crack bridging mechanism, where the propagating crack leaves fibers

or second-phase particles intact. The unbroken fibers or particles exert a traction force on the crack

faces, much like the Dugdale-Barenblatt strip-yield model [18, 19]. The fibers eventually rupture

when the stress reaches a critical value. According to Equation (3.42) and Equation (3.43), the

FIGURE 6.30 The fiber bridging mechanism for

ceramic toughening.