Page 309 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 309

1656_C006.fm Page 289 Monday, May 23, 2005 5:50 PM

Fracture Mechanisms in Nonmetals 289

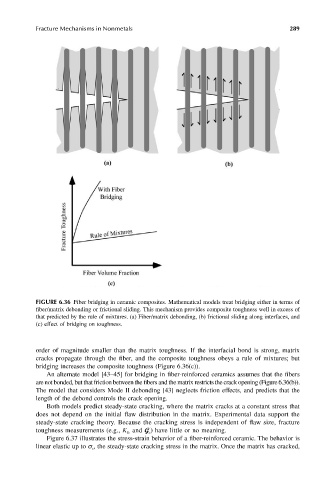

FIGURE 6.36 Fiber bridging in ceramic composites. Mathematical models treat bridging either in terms of

fiber/matrix debonding or frictional sliding. This mechanism provides composite toughness well in excess of

that predicted by the rule of mixtures. (a) Fiber/matrix debonding, (b) frictional sliding along interfaces, and

(c) effect of bridging on toughness.

order of magnitude smaller than the matrix toughness. If the interfacial bond is strong, matrix

cracks propagate through the fiber, and the composite toughness obeys a rule of mixtures; but

bridging increases the composite toughness (Figure 6.36(c)).

An alternate model [43–45] for bridging in fiber-reinforced ceramics assumes that the fibers

are not bonded, but that friction between the fibers and the matrix restricts the crack opening (Figure 6.36(b)).

The model that considers Mode II debonding [43] neglects friction effects, and predicts that the

length of the debond controls the crack opening.

Both models predict steady-state cracking, where the matrix cracks at a constant stress that

does not depend on the initial flaw distribution in the matrix. Experimental data support the

steady-state cracking theory. Because the cracking stress is independent of flaw size, fracture

toughness measurements (e.g., K and G ) have little or no meaning.

Ic

c

Figure 6.37 illustrates the stress-strain behavior of a fiber-reinforced ceramic. The behavior is

linear elastic up to σ , the steady-state cracking stress in the matrix. Once the matrix has cracked,

c