Page 313 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 313

1656_C006.fm Page 293 Monday, May 23, 2005 5:50 PM

Fracture Mechanisms in Nonmetals 293

(a)

(b)

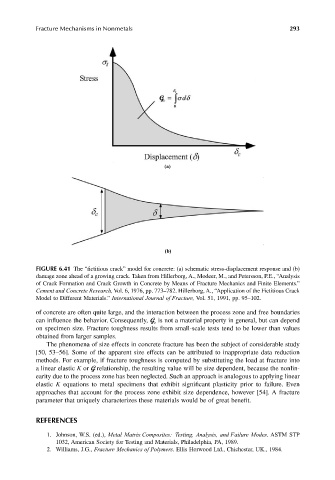

FIGURE 6.41 The “fictitious crack” model for concrete: (a) schematic stress-displacement response and (b)

damage zone ahead of a growing crack. Taken from Hillerborg, A., Modeer, M., and Petersson, P.E., “Analysis

of Crack Formation and Crack Growth in Concrete by Means of Fracture Mechanics and Finite Elements.”

Cement and Concrete Research, Vol. 6, 1976, pp. 773–782. Hillerborg, A., “Application of the Fictitious Crack

Model to Different Materials.” International Journal of Fracture, Vol. 51, 1991, pp. 95–102.

of concrete are often quite large, and the interaction between the process zone and free boundaries

can influence the behavior. Consequently, G is not a material property in general, but can depend

c

on specimen size. Fracture toughness results from small-scale tests tend to be lower than values

obtained from larger samples.

The phenomena of size effects in concrete fracture has been the subject of considerable study

[50, 53–56]. Some of the apparent size effects can be attributed to inappropriate data reduction

methods. For example, if fracture toughness is computed by substituting the load at fracture into

a linear elastic K or G relationship, the resulting value will be size dependent, because the nonlin-

earity due to the process zone has been neglected. Such an approach is analogous to applying linear

elastic K equations to metal specimens that exhibit significant plasticity prior to failure. Even

approaches that account for the process zone exhibit size dependence, however [54]. A fracture

parameter that uniquely characterizes these materials would be of great benefit.

REFERENCES

1. Johnson, W.S. (ed.), Metal Matrix Composites: Testing, Analysis, and Failure Modes. ASTM STP

1032, American Society for Testing and Materials, Philadelphia, PA, 1989.

2. Williams, J.G., Fracture Mechanics of Polymers. Ellis Horwood Ltd., Chichester, UK., 1984.