Page 152 - Fundamentals of Magnetic Thermonuclear Reactor Design

P. 152

134 Fundamentals of Magnetic Thermonuclear Reactor Design

external thermal perturbations that may occur, for example, as a result of crack-

ing of the impregnating compound.

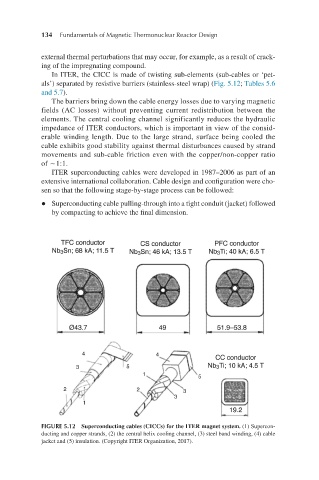

In ITER, the CICC is made of twisting sub-elements (sub-cables or ‘pet-

als’) separated by resistive barriers (stainless-steel wrap) (Fig. 5.12; Tables 5.6

and 5.7).

The barriers bring down the cable energy losses due to varying magnetic

fields (AC losses) without preventing current redistribution between the

elements. The central cooling channel significantly reduces the hydraulic

impedance of ITER conductors, which is important in view of the consid-

erable winding length. Due to the large strand, surface being cooled the

cable exhibits good stability against thermal disturbances caused by strand

movements and sub-cable friction even with the copper/non-copper ratio

of ∼1:1.

ITER superconducting cables were developed in 1987–2006 as part of an

extensive international collaboration. Cable design and configuration were cho-

sen so that the following stage-by-stage process can be followed:

l Superconducting cable pulling-through into a tight conduit (jacket) followed

by compacting to achieve the final dimension.

FIGURE 5.12 Superconducting cables (CICCs) for the ITER magnet system. (1) Supercon-

ducting and copper strands, (2) the central helix cooling channel, (3) steel band winding, (4) cable

jacket and (5) insulation. (Copyright ITER Organization, 2017).