Page 250 - Fundamentals of Magnetic Thermonuclear Reactor Design

P. 250

First Wall Components Chapter | 7 231

A concise description of the testing and technological complex operated at

Efremov Institute since the beginning of the 2000s is given next.

The complex uses an industrialised approach to the development and testing

of multilayer in-chamber components, which are part of Russia’s commitment

under the ITER Joint Implementation Agreement (179 first-wall panels com-

prising 40% of the FW surface and all of the 60 central divertor assemblies).

The complex will later be used for preinstallation testing of ITER divertor tar-

gets manufactured in Japan and the EU.

The complex includes the following:

l The TSEFEY-M and IDTF electron beam test facilities [6] (Table 7.3).

l Process equipment for thermal-vacuum joining of multilayer structures:

vacuum brazing devices (for Be–CuCrZr Cu–CuCrZr joints) vacuum

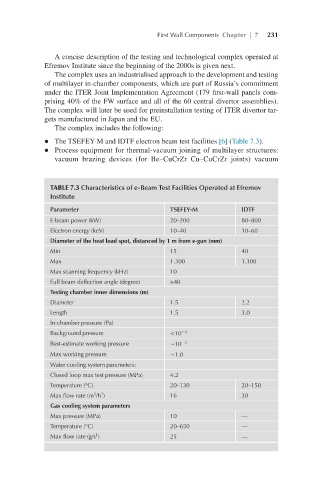

TABLE 7.3 Characteristics of e-Beam Test Facilities Operated at Efremov

Institute

Parameter TSEFEY-M IDTF

E-beam power (kW) 20–200 80–800

Electron energy (keV) 10–40 10–60

Diameter of the heat load spot, distanced by 1 m from e-gun (mm)

Min 15 40

Max 1.300 1.300

Max scanning frequency (kHz) 10

Full beam deflection angle (degree) ±40

Testing chamber inner dimensions (m)

Diameter 1.5 2.2

Length 1.5 3.0

In-chamber pressure (Pa)

Background pressure <10 −4

Best-estimate working pressure ∼10 −2

Max working pressure ∼1.0

Water cooling system parameters:

Closed loop max test pressure (MPa) 4.2

Temperature (°C) 20–130 20–150

3

1

Max flow rate (m /h ) 16 30

Gas cooling system parameters

Max pressure (MPa) 10 —

Temperature (°C) 20–650 —

1

Max flow rate (g/s ) 25 —