Page 337 - Fundamentals of Magnetic Thermonuclear Reactor Design

P. 337

280–600

280–900

∼90

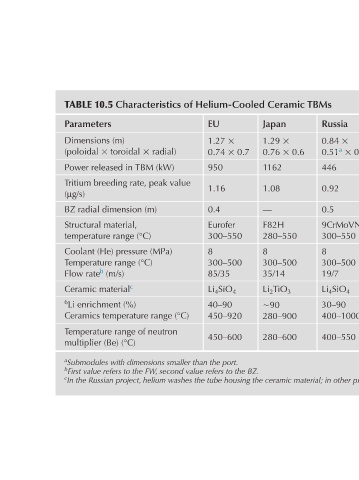

c In the Russian project, helium washes the tube housing the ceramic material; in other projects, helium flows inside the tube with ceramic material outside.

450–920

450–600

40–70

450–900

570–680

40

400–950

400–620

90

400–1000

400–550

Russia Japan USA Korea China 1.74 × 0.4 × 1.49 × 1.66 × 0.84 × 0.53 × 0.6 0.71 a × 0.6 0.91 × 0.5 0.67 a × 0.48 0.51 a × 0.75 1088 330 1455 950 446 0.98 — 2.93 1.18 0.92 — 0.4 — 0.4 0.5 F82H Ferritic steel Eurofer Eurofer 9CrMoVNb 280–550 300–550 300–550 300–550 300–550 15

30–90

TABLE 10.5 Characteristics of Helium-Cooled Ceramic TBMs

Japan 1.29 × 0.76 × 0.6 1162 1.08 — F82H 280–550 8 300–500 35/14 Li 2 TiO 3 ∼90 280–900 280–600

1.27 × 0.74 × 0.7 Eurofer 300–550 300–500 Li 4 SiO 4 40–90 450–920 450–600

EU 950 1.16 0.4 8 85/35

(poloidal × toroidal × radial) Power released in TBM (kW) Tritium breeding rate, peak value Coolant (He) pressure (MPa) Ceramics temperature range (°C) Temperature range of neutron a Submodules with dimensions smaller than the port. b First value refers to the FW, second value refers to the BZ.

Parameters Dimensions (m) (µg/s) BZ radial dimension (m) Structural material, temperature range (°C) Temperature range (°C) Flow rate b (m/s) Ceramic material c 6 Li enrichment (%) multiplier (Be) (°C)