Page 61 - Fundamentals of Magnetic Thermonuclear Reactor Design

P. 61

44 Fundamentals of Magnetic Thermonuclear Reactor Design

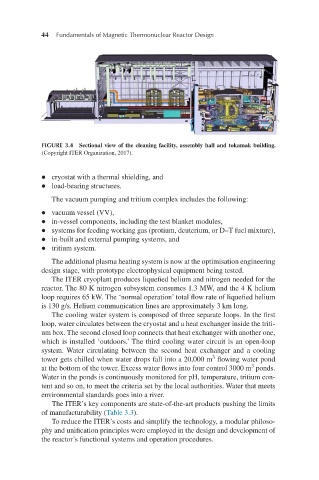

FIGURE 3.4 Sectional view of the cleaning facility, assembly hall and tokamak building.

(Copyright ITER Organization, 2017).

l cryostat with a thermal shielding, and

l load-bearing structures.

The vacuum pumping and tritium complex includes the following:

l vacuum vessel (VV),

l in-vessel components, including the test blanket modules,

l systems for feeding working gas (protium, deuterium, or D–T fuel mixture),

l in-built and external pumping systems, and

l tritium system.

The additional plasma heating system is now at the optimisation engineering

design stage, with prototype electrophysical equipment being tested.

The ITER cryoplant produces liquefied helium and nitrogen needed for the

reactor. The 80 K nitrogen subsystem consumes 1.3 MW, and the 4 K helium

loop requires 65 kW. The ‘normal operation’ total flow rate of liquefied helium

is 130 g/s. Helium communication lines are approximately 3 km long.

The cooling water system is composed of three separate loops. In the first

loop, water circulates between the cryostat and a heat exchanger inside the triti-

um box. The second closed loop connects that heat exchanger with another one,

which is installed ‘outdoors.’ The third cooling water circuit is an open-loop

system. Water circulating between the second heat exchanger and a cooling

3

tower gets chilled when water drops fall into a 20,000 m flowing water pond

3

at the bottom of the tower. Excess water flows into four control 3000 m ponds.

Water in the ponds is continuously monitored for pH, temperature, tritium con-

tent and so on, to meet the criteria set by the local authorities. Water that meets

environmental standards goes into a river.

The ITER’s key components are state-of-the-art products pushing the limits

of manufacturability (Table 3.3).

To reduce the ITER’s costs and simplify the technology, a modular philoso-

phy and unification principles were employed in the design and development of

the reactor’s functional systems and operation procedures.