Page 209 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 209

164 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

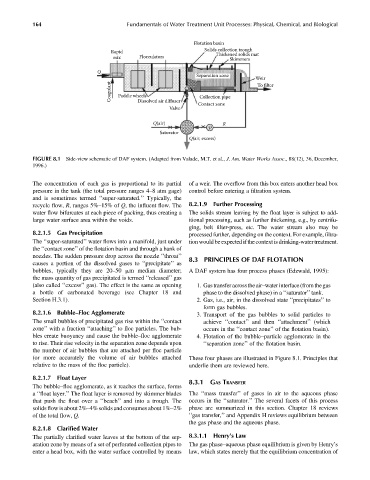

Flotation basin

Solids collection trough

Rapid Thickened solids mat

mix Flocculators Skimmers

Q

Separation zone

Weir

Coagulant Paddle wheels Collection pipe

To filter

Dissolved air diffuser

Contact zone

Valve

Q(air) R

P

Saturator

Q(air, excess)

FIGURE 8.1 Side-view schematic of DAF system. (Adapted from Valade, M.T. et al., J. Am. Water Works Assoc., 88(12), 36, December,

1996.)

The concentration of each gas is proportional to its partial of a weir. The overflow from this box enters another head box

pressure in the tank (the total pressure ranges 4–8 atm gage) control before entering a filtration system.

and is sometimes termed ‘‘super-saturated.’’ Typically, the

recycle flow, R, ranges 5%–15% of Q, the influent flow. The 8.2.1.9 Further Processing

water flow bifurcates at each piece of packing, thus creating a The solids stream leaving by the float layer is subject to add-

large water surface area within the voids. itional processing, such as further thickening, e.g., by centrifu-

ging, belt filter-press, etc. The water stream also may be

8.2.1.5 Gas Precipitation processed further, depending on the context. For example, filtra-

The ‘‘super-saturated’’ water flows into a manifold, just under tion would beexpected ifthe context isdrinking-watertreatment.

the ‘‘contact zone’’ of the flotation basin and through a bank of

nozzles. The sudden pressure drop across the nozzle ‘‘throat’’ 8.3 PRINCIPLES OF DAF FLOTATION

causes a portion of the dissolved gases to ‘‘precipitate’’ as

bubbles, typically they are 20–50 mm median diameter; A DAF system has four process phases (Edzwald, 1995):

the mass quantity of gas precipitated is termed ‘‘released’’ gas

(also called ‘‘excess’’ gas). The effect is the same as opening 1. Gas transferacrossthe air–water interface (from thegas

a bottle of carbonated beverage (see Chapter 18 and phase to the dissolved phase) in a ‘‘saturator’’ tank.

Section H.3.1). 2. Gas, i.e., air, in the dissolved state ‘‘precipitates’’ to

form gas bubbles.

8.2.1.6 Bubble–Floc Agglomerate 3. Transport of the gas bubbles to solid particles to

The small bubbles of precipitated gas rise within the ‘‘contact achieve ‘‘contact’’ and then ‘‘attachment’’ (which

zone’’ with a fraction ‘‘attaching’’ to floc particles. The bub- occurs in the ‘‘contact zone’’ of the flotation basin).

bles create buoyancy and cause the bubble–floc agglomerate 4. Flotation of the bubble–particle agglomerate in the

to rise. Their rise velocity in the separation zone depends upon ‘‘separation zone’’ of the flotation basin.

the number of air bubbles that are attached per floc particle

(or more accurately the volume of air bubbles attached These four phases are illustrated in Figure 8.1. Principles that

relative to the mass of the floc particle). underlie them are reviewed here.

8.2.1.7 Float Layer

8.3.1 GAS TRANSFER

The bubble–floc agglomerate, as it reaches the surface, forms

a ‘‘float layer.’’ The float layer is removed by skimmer blades The ‘‘mass transfer’’ of gases in air to the aqueous phase

that push the float over a ‘‘beach’’ and into a trough. The occurs in the ‘‘saturator.’’ The several facets of this process

solids flow is about 2%–4% solids and consumes about 1%–2% phase are summarized in this section. Chapter 18 reviews

of the total flow, Q. ‘‘gas transfer,’’ and Appendix H reviews equilibrium between

the gas phase and the aqueous phase.

8.2.1.8 Clarified Water

The partially clarified water leaves at the bottom of the sep- 8.3.1.1 Henry’s Law

aration zone by means of a set of perforated collection pipes to The gas phase–aqueous phase equilibrium is given by Henry’s

enter a head box, with the water surface controlled by means law, which states merely that the equilibrium concentration of