Page 53 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 53

8 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

1.3.6 FUTURE OF TREATMENT kind of separation. Then to make any process feasible from an

engineering point of view, there must be a compromise

There is little doubt that technologies will continue to evolve,

between energy cost and the speed of the process (the more

particularly if the market exists for improved applications of

irreversible the process, the higher is its velocity, but the higher

unit processes. Looking at the unit processes, some 15 are

the energy cost). The second law places an inherent limit on

listed in Table 1.1; they were identified based upon funda-

what may be expected.

mental principles. Of the 15 identified, and looking at the

underlying principles of each, the question would be as

follows: Could principles not yet used be applied for separat- 1.4 TREATMENT TRAINS

ing contaminants from water? While any predictions are

uncertain by nature, we could say with safety that any new The configurations of unit processes that may comprise treat-

ment trains are perhaps as numerous as there are combinations of

ones would have to be based on remaining principles that may

the unit processes listed in Table 1.1. Those that are most

cause a change of state of a substance.

common are (1) for potable water and (2) for wastewater.

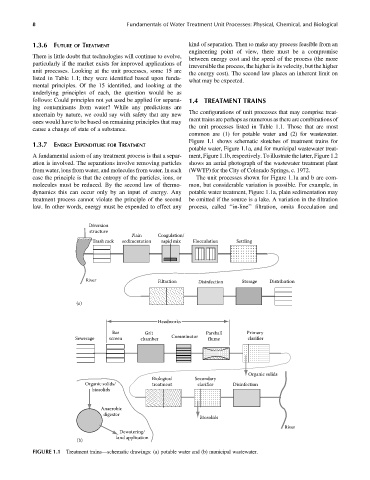

Figure 1.1 shows schematic sketches of treatment trains for

1.3.7 ENERGY EXPENDITURE FOR TREATMENT

potable water, Figure 1.1a, and for municipal wastewater treat-

A fundamental axiom of any treatment process is that a separ- ment, Figure1.1b, respectively. Toillustratethe latter, Figure1.2

ation is involved. The separations involve removing particles shows an aerial photograph of the wastewater treatment plant

from water, ions from water, and molecules from water. In each (WWTP) for the City of Colorado Springs, c. 1972.

case the principle is that the entropy of the particles, ions, or The unit processes shown for Figure 1.1a and b are com-

molecules must be reduced. By the second law of thermo- mon, but considerable variation is possible. For example, in

dynamics this can occur only by an input of energy. Any potable water treatment, Figure 1.1a, plain sedimentation may

treatment process cannot violate the principle of the second be omitted if the source is a lake. A variation in the filtration

law. In other words, energy must be expended to effect any process, called ‘‘in-line’’ filtration, omits flocculation and

Diversion

structure

Plain Coagulation/

Trash rack sedimentation rapid mix Flocculation Settling

River Filtration Disinfection Storage Distribution

(a)

Headworks

Bar Grit Parshall Primary

Sewerage screen chamber Comminutor flume clarifier

Organic solids

Biological Secondary

Organic solids/ treatment clarifier Disinfection

biosolids

Anaerobic

digester

Biosolids

River

Dewatering/

land application

(b)

FIGURE 1.1 Treatment trains—schematic drawings: (a) potable water and (b) municipal wastewater.